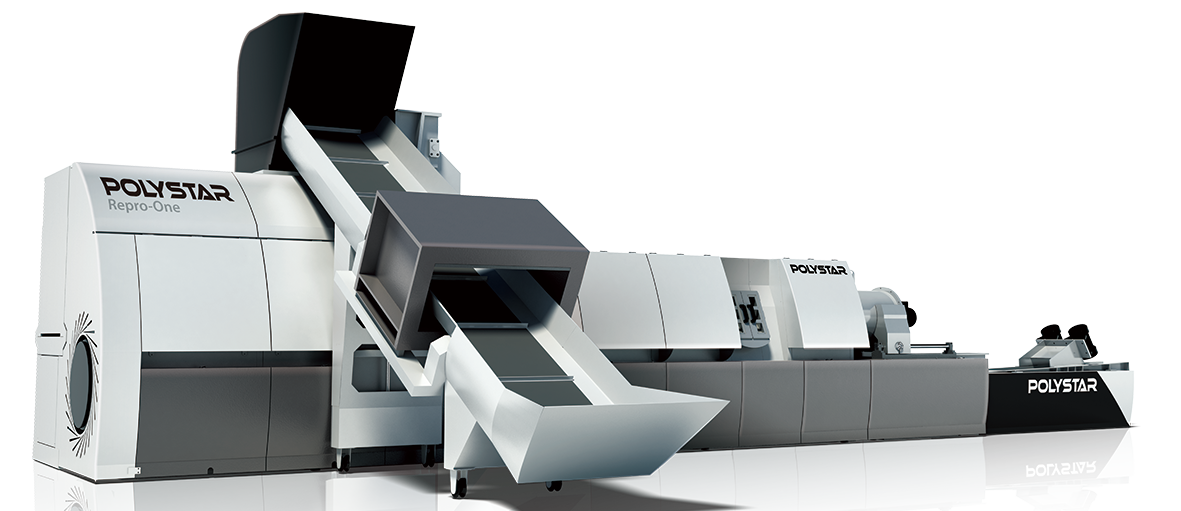

| Direct Feeding Pelletizing Technology |

| - Single step process: Extrusion + Degassing + Filtration + Pelletizing - Less processing steps + Less power consumption - Gentle-process-minimal material property change |

| Video |

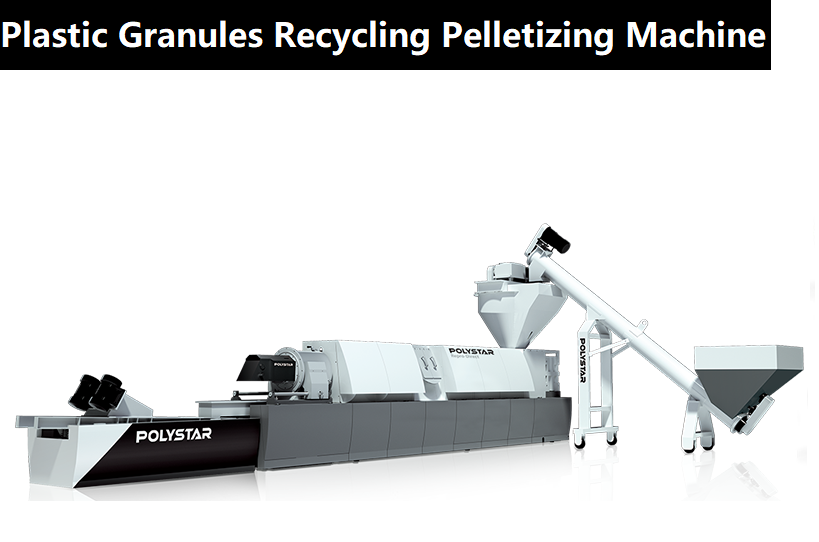

| Plastic Granules Recycling Pelletizing Machine |

| POLYSTAR Exhibition | |

| Visit POLYSTAR at worldwide exhibition for Plastic Granules Recycling Pelletizing Machine | |

| |

|  |

| Shipping photos | |

| Plastic Granules Recycling Pelletizing Machine | |

|  |

| Recommend products | ||

|  |  |

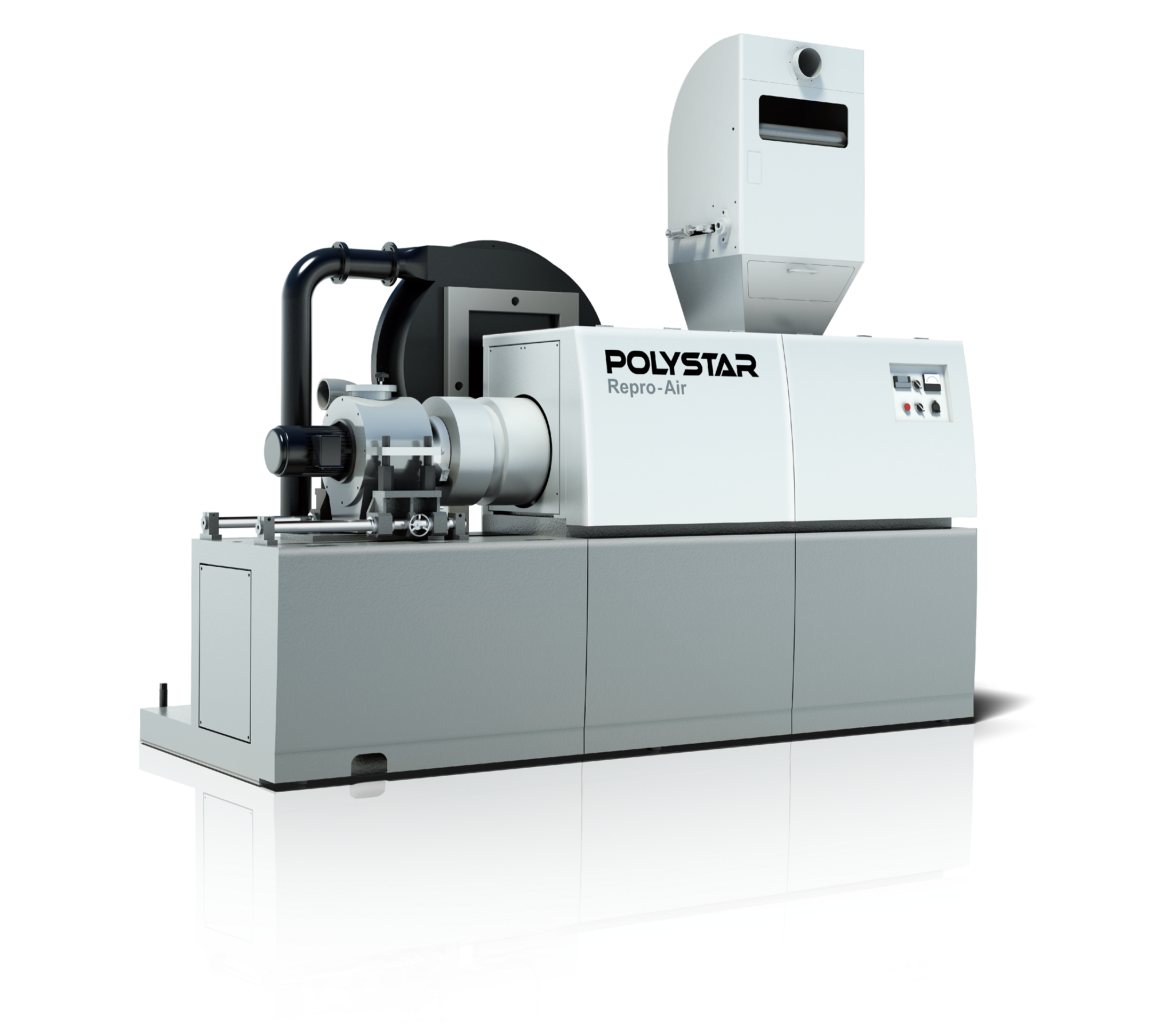

Shredder integrated recycling machine | Twin Head Blown Film Machine | Air cooled recycling machine |

Recycling Materials | Possible Product | Recycling Materials |

| - PP raffia - Woven - PE/PP Film waste | - T-shirt bag - Bottom sealed flat bag - shopping bag - Supermarket Bag - Garbage Bag | - In-house PE waste - Film rolls - T-shirt bag cut-offs - Leno bags |

Find more info on POLYSTAR Official Website: www.polystarco.com | ||

Taiwantrade.com and iDealEZ.com uses analytical cookies and other tracking technologies to offer you the best possible user experience. By using our website, you acknowledge and agree to our cookie policy.

For more information on cookies or changing your cookies settings, read Taiwantrade & iDealEZ’s Privacy Policy.