| Model | CE-AB (2 Layer Blown Film Machine) |

| Product | HDPE/LDPE/LLDPE film |

| Film layer | AB 2 layer |

| Material | Recycled material, LDPE/LLDPE blend, HDPE with CaCO3, Biodegradable or virgin raw material |

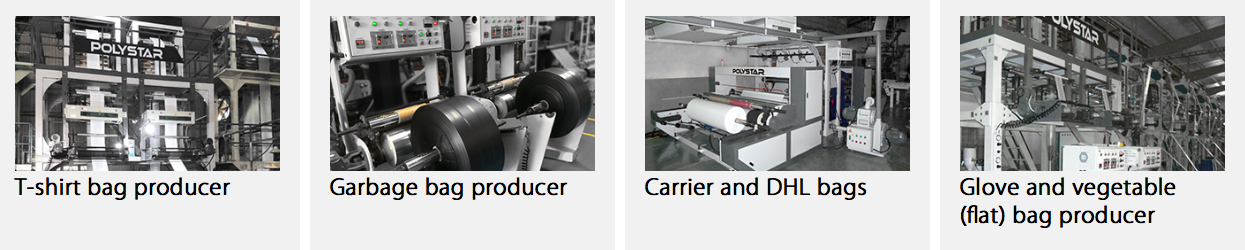

| HDPE | T-shirt bag, Garbage bag, Furniture cover film, Laundry bag |

| LDPE | Agriculture film, Construction cover, Dust cover, Furniture cover, Pillow/mattress bag |

| Optional Devices | Auto loader, masterbatch dosing system, rotary die head, bubble controller, corona treater, embossing roller, automatic winder, double winder |

| Production Output | ||

2 Layer Blown Film Machine | ||

| Model | CE-AB-55-55 | CE-AB-65-65 |

| Screw Diameter | 55mm+55mm | 65mm+65mm |

| Max. Width | 1000mm | 1500mm |

| Output | 80-90 kg/hr | 130-150 kg/hr |

| Thickness | 0.01-0.1 mm | 0.01-0.1mm |

| Possible Product | ||

2 Layer Blown Film Machine | ||

|  |  |

Packaging Film | Agricultural Film | Mulch Film |

Company profile | |

2 Layer Blown Film Machine | |

| |

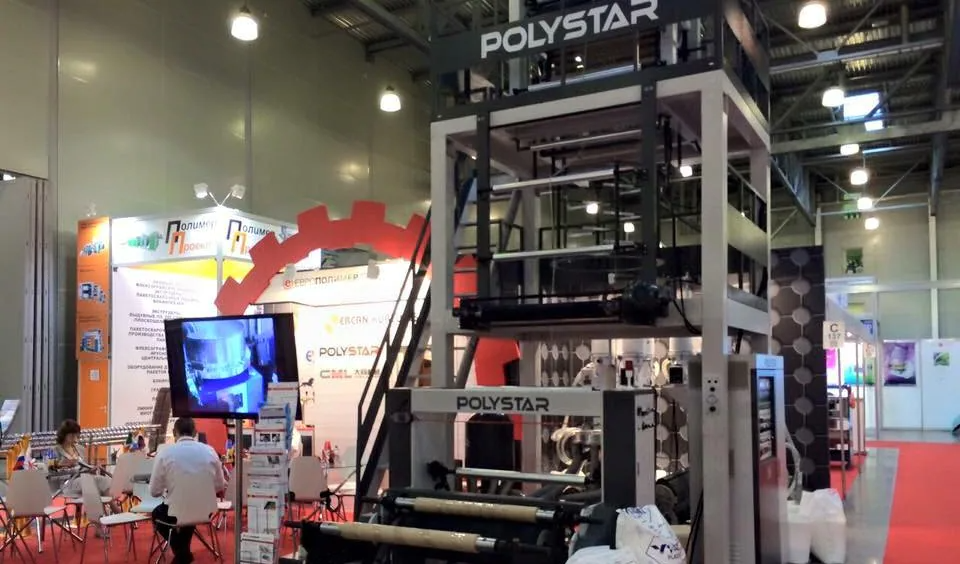

| Our Experience, Your Advantage | |

| 32 years of experience Through years of manufacturing and designing experiences and continuous customer feedback, POLYSTAR has become one of the global leaders in the field through 3 generation of technological evolution. A global leader with 4,180 machines installed More than 4,180 machines have been installed since 1988. Proven success in Asia, Africa, Europe, Middle East & America. Satisfied customers in 105 countries POLYSTAR has been working closely with plastic producers around the world and has established itself as a premium brand that offers reliable and high performing machines in the market. | |

Blown Film Industry | |

| |

| Plastic film manufacturer | Plastic bag manufacturer |

POLYSTAR Taiwan produces a wide range of blown film machine, including 2 Layer Blown Film Machine, mono-layer, multi-layer, HDPE/LDPE/PP blown film machine, double-die-head blown film machine...etc. POLYSTAR Taiwan manufactures 2 Layer Blown Film Machine with higher and lower capacity available from 30-200 kg/hr. Model CE65/65-1400 2 Layer Blown Film Machine produces 1250mm maximum films, with capacity of 140-160 kg/hr. | POLYSTAR’s twin (two) head blown film machine is very popular amongst bag producers of T-shirt, supermarket, flat, garbage and bottom-sealed bags (ranges from 200~600mm in width, in HDPE and LDPE). This high speed line provides a much faster return on investment comparing to a blown film machine equipped with IBC. In the double head blown film machines, one can reach much higher output even when producing at small film width. It is the perfect choice for bag makers who are looking for less expensive machines with higher output and good film quality. |

| |

Recycling Industry | |

|  |

| PP raffia, woven and FIBC supplier | BOPP and laminated film supplier |

| In-house waste generated from the production of PP woven bags, non-woven, jumbo bags, PP raffia, PP woven sacks and tapes. The recycled PP pellets can be reused (100%) for production. In most cases in circular weaving looms and tapelines. | BOPP and stretch film scraps and film on-roll can be turned into high quality pellets for reprocessing. POLYSTAR’s advanced cutter-compactor system can process material that is typically more difficult to recycle due to its special property, such as printed BOPP and stretch film that one normally faces problem with the traditional recycling systems. |

| |

Work with POLYSTAR | |

| High quality film roll High precision die head and cooling air ring of 2 Layer Blown Film Machine provide good film thickness control and resistance. |

| Manufacturing with Precision CE certified 2 Layer Blown Film Machine with total quality control Adopts the latest design and manufacturing of screw and barrel to achieve maximum efficiency Strong research and design team |

| Service and Communication - Overseas 2 Layer Blown Film Machine installation service and training are available - Machine warranty with in-time spare parts delivery - Fast online trouble shooting |

| Worldwide Exhibition | |

2 Layer Blown Film Machine | |

|  |

Are you from the EU regions?

Taiwantrade.com and iDealEZ.com uses analytical cookies and other tracking technologies to offer you the best possible user experience. By using our website, you acknowledge and agree to our cookie policy.

For more information on cookies or changing your cookies settings, read Taiwantrade & iDealEZ’s Privacy Policy.