2. The compact design makes it not only space-saving but easy to operate and ready-to-use

| Specifications of Blown Film Extruder For Medical Bag | |

| Model | MB |

| Product | HDPE film |

| Film layer | One layer |

| Material | Recycled material, HDPE with CaCO3, LDPE/LLDPE blend, biodegradable or virgin raw material |

| Application | T-shirt bag, Shopping bag, Supermarket bag, Flat bag |

| Production Output of Blown Film Extruder For Medical Bag | ||

| Model | MB45 | MB55 |

| Extruder Screw Diameter | 45mm | 55mm |

| Maximum Film Width | 650mm | 800mm |

| Output (kg/hr) | 30~40kg/hr | 40~50kg/hr |

| Film thickness | HDPE : 0.008~0.04mm LDPE : 0.02~0.04mm | |

Blown Film Extruder For Medical Bag |

| The machine produces |

|

| Possible Products of Blown Film Extruder For Medical Bag |

Blown Film Extruder For Medical Bag : Simple in Design, Productive and Flexible | |

| Blown Film Extruder For Medical Bag provides a good solution for economic but good quality film. Suitable for general packaging products such as T-shirt bags, supermarket bags, flat bags and many others. | |

| Simple Production of Blown Film Extruder For Medical Bag Film width of blow film machine available from 150mm to 800mm (5 to 31 inch) and can be customized depending on customer's requirement, suitable for both HDPE and LDPE film. |

| Simple Mixing of Blown Film Extruder For Medical Bag The special screw design provides good mixing for both colored (with masterbatches) and transparent film. A percentage of recycled material and Calcium carbonate can also be used in the mixture. |

|  |  |

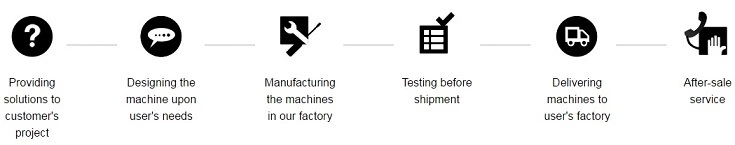

| Customized machines

| |

Are you from the EU regions?

Taiwantrade.com and iDealEZ.com uses analytical cookies and other tracking technologies to offer you the best possible user experience. By using our website, you acknowledge and agree to our cookie policy.

For more information on cookies or changing your cookies settings, read Taiwantrade & iDealEZ’s Privacy Policy.