| |

| High Speed Blown Film Installation provides a good solution for general packaging and produces quality film. Suitable for general packaging products such as T-shirt bags, supermarket bags, flat bags and many others. High Speed Blown Film Installation's film width available from 800 mm to 2300 mm and can be customized depending on customer's requirement, suitable for both HDPE and LDPE film. | |

| |

| The specially designed High Speed Blown Film Installation has good ability for melting and mixing material with masterbatch /additives. | |

| High Speed Blown Film Installation is a simple and flexible machine that can produce HDPE or LDPE, by simply changing the die head and air ring. |

| High Speed Blown Film Installation double winding unit, manual or automatic type can be added for single-layer film for lamination.Back-to Back or Top-Down types are available depending on customer's factory space and layout. |

| |

| One set of High Speed Blown Film Installation and one set of co-extrusion two layer blown film machine are installed in Denmark. As located in western Denmark, this company supplies multiple kinds of bags not only for local market but also neighboring countries such as Germany, Norway and Sweden. The customer also installed printing and bag making machine in the factory. By running a complete production line from blown film extrusion, printing, to bag making, quality is thoroughly controlled by them to sell the high value-added end product with good reputation. | |

|  |

| One of the leading plastic net producer in Cape Town, South African purchased a High Speed Blown Film Installation for producing 80~100 micron HDPE film from Polystar. In 2013, the customer met Polystar at K show and had a long discussion about his need of this blown film machine. Right after K show, customer decided to add a High Speed Blown Film Installation made by Polystar to his production line. Polystar designed a machine for the customer to produce HDPE film with the width of 800mm and thickness 80-100 micron. In addition to the extruder, Polystar also designed a winder to enable the customer to cut the side of the film and roll the two sheets together. | Another large sized High Speed Blown Film Installation was installed in Uganda for producing 1500mm LDPE film. The 1500mm LDPE film will be used for mattress packaging. The buyer of this mattress packaging film blowing machine used to import the mattress packaging films from China. Since the demand for mattress packaging bags is increasing year by year, he needed to import more and more films from outside of the country. In the year of 2012, he decided to try to produce the mattress packaging films by himself. After the first order of mattress film blowing machine in 2012, this film producer in Uganda kept ordering one or two High speed film blown machines for making mattress packaging films every year. Till the year of 2014, he already has 5 sets film blowing machines to produce mattress packaging films. |

| High quality film roll High precision die head and cooling air ring of High Speed Blown Film Installation provide good film thickness control and resistance. |

| Manufacturing with Precision CE certified High Speed Blown Film Installation with total quality control. Adopts the latest design and manufacturing of screw and barrel to achieve maximum efficiency Strong research and design team. |

| Service and Communication Overseas High Speed Blown Film Installation installation service and training are available Machine warranty with in-time spare parts delivery Fast online trouble shooting. |

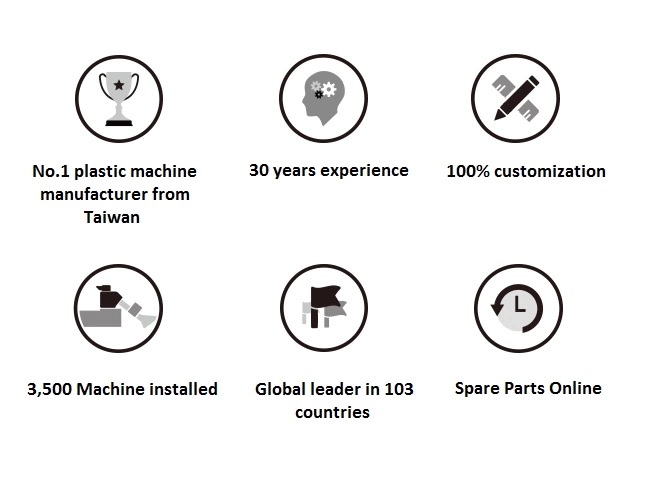

Our Experience, Your Advantage  | |

Are you from the EU regions?

Taiwantrade.com and iDealEZ.com uses analytical cookies and other tracking technologies to offer you the best possible user experience. By using our website, you acknowledge and agree to our cookie policy.

For more information on cookies or changing your cookies settings, read Taiwantrade & iDealEZ’s Privacy Policy.