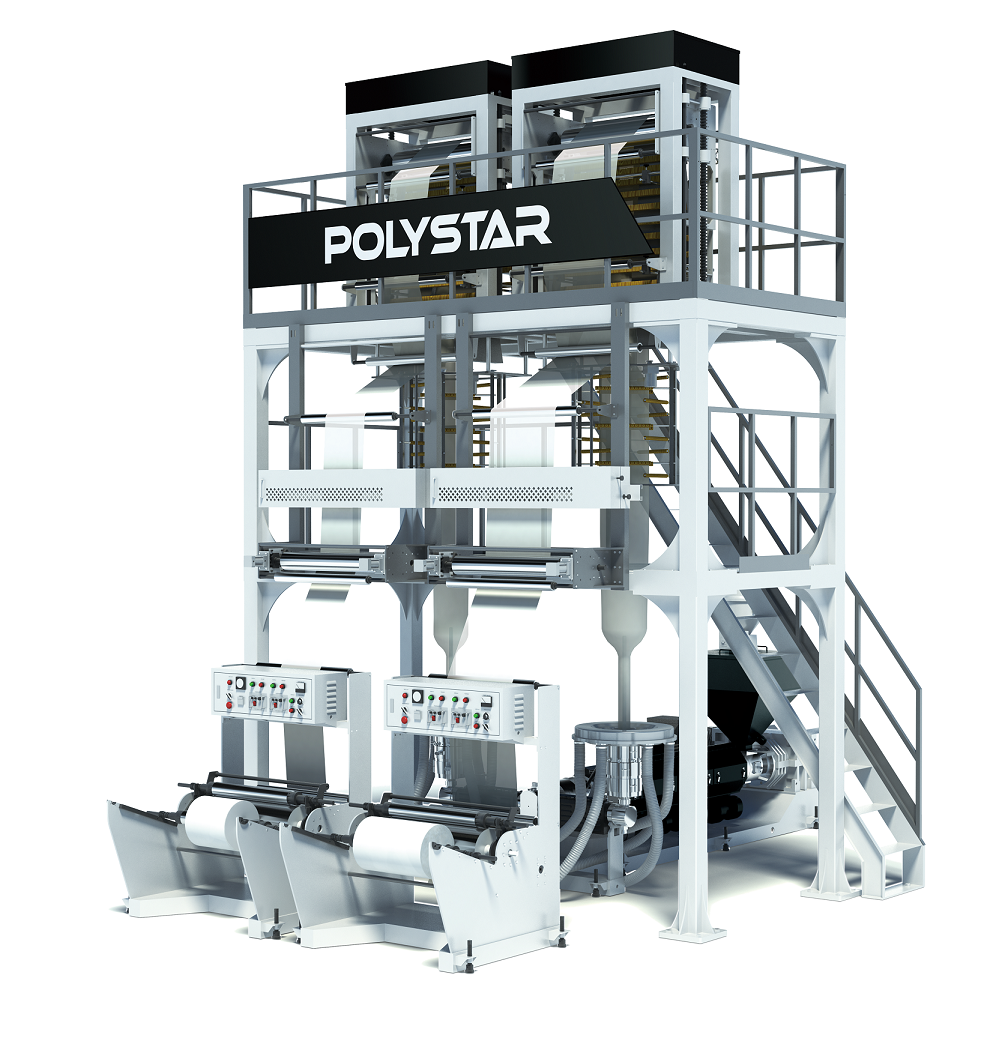

| Washed Flakes Recycling Machine |

| - One-step direct technology with cutting + extrusion + pelletizing - Very easy to install, operate and perform maintenance - Our high-performance Printed Film Recycling System can help to provide better productivity and increased efficiency. - Output : 100-1200kg/hr |

Specifications | |

| Washed Flakes Recycling Machine | |

Model Name | Repro-Flex Plus (Washed Flakes Recycling Machine) |

Final Product | Plastic pellets/granule |

Machine Components | Conveyor belt, cutter compactor shredder, extruder, pelletizing unit, water cooling unit, drying unit, silo tank |

Recycling Material | HDPE, LDPE, LLDPE, PP, BOPP |

Feeding | Conveyor belt |

Screw Material | SACM-465 |

Degassing | Double vented or triple degassing (customized) |

Cutting Type | Hot die face pelletizing |

Cooling | Water cooled |

Voltage | Customized |

Optional Devices | Metal detector(S+S) , Nip roller for film roll feeding , Additive feeder for masterbatch |

Warranty | 1 year |

Technical Assistance | Engineers available to service machinery overseas |

Successful Projects | |

| Washed Flakes Recycling Machine | |

| |

Post-consumer recycling (PE/PP) growing in Russia | |

| Post-consumer recycling requires several processing steps such as sorting (material separation), size reduction, washing, drying and pelletizing in order to achieve good quality recycled pellets as the end product. See a brief video introduction : Good degassing and filtration are probably the most important processes in pelletizing machines when it comes to post-consumer recycling. In many occasions, a Washed Flakes Recycling Machine is preferred by professional recyclers who focus on post-consumer recycling. The washed material is fed into the compactor for a quick densifying process (which at the same time further dries the material by natural heat and friction); this helps to stabilize the material feeding into the extruder. The material then goes into the first (main) extruder for the filtration process and a two-vented degassing (installed with high efficiency vacuum system). The material then passes through an open area for the third and final degassing, and enters the second stage (short) extruder where the second filtering process is done. | |

|  |

The Washed Flakes Recycling Machine significantly improves the quality of the recycled pellets as the washed material goes through two filtration and three degassing steps in both extruders combined. As a result, the final pelletizing process becomes more stable and easier to operate because the material is already well prepared and pre-conditioned.

A post-consumer recycler located in Belgorod, Russia who is dedicated in the recycling of municipal waste has a complete set up: The automatic sorting lines initially separate paper, glass, metal and plastic. The plastics are then separated by groups: 1) PET bottles, 2) films of HDPE and LDPE and 3) rigid plastic and followed by two washing lines - One for PET bottle and another for plastic films. After washing and drying the process is completed in the POLYSTAR pelletizing recycling machine. The recycled pellets are mainly used for producing plastic boxes for vegetables. Updates of POLYSTAR in the Russian recycling market: In Russia, 68 sets of POLYSTAR plastic pelletizing machine have been installed since 2012. With strong know-how and service team from our local agent in Russia - Evropolimer, we can provide customers with the most suitable and simplest recycling solutions, followed by installation, training, spare parts and maintenance services. | |

| |

POLYSTAR extruder + FIMIC Filter – simple solution for post-consumer recycling | |

The need of a more automatic, self-cleaning filter to reduce labor cost and improve efficiency has been a key factor for professional post-consumer recyclers, for applications such as paper label removal and milk/shampoo bottles. However, most of the solutions available in the market today have a very high initial investment cost and even higher maintenance cost that follow (mainly because of expensive spare parts), which could be challenging as the operation cost remains high and the return on investment is too slow. The POLYSTAR extruder pelletizer and FIMIC filtration system combination provide professional recyclers with a simple, cost-effective solution that has a much lower operation and maintenance cost, which results in higher profit margin. Fast delivery time and fast return on investment (thanks to lower initial equipment investment) make things even easier for recyclers who need to have a machine up and running within a short time. The POLYSTAR + FIMIC combo has been in operation since 2016, with numerous installations in the United States, Sweden, the United Kingdom, Australia, Turkey, Colombia, Portugal, Russia, Ghana and Latvia, with ongoing projects for Japan and Canada. FIMIC advantage The FIMIC filter is much simpler, because it requires only 30 minutes and one operator to replace a screen, whereas other solutions in the market generally require 1.5 ~ 2 hours. Less investment and operation/maintenance cost The FIMIC system does not need to install an extra pre-filter to protect the screen against possible damage as the “scraper” collects the contamination immediately from the screen. The melt losses are also less because the filter discharges only when it is needed (instead of discharging continuously like in some filter systems). At last, the cost of spare parts of the FIMIC filter is also less expensive comparing to its other European competitors in the market. POLYSTAR advantage The design of the POLYSTAR pelletizing extruder is simple, and focused on the most important features for recyclers to have a stable operation in order to reduce down-time and lower production cost. The emphasis on easy user-interface makes sure that the Initial training time and cost for (new) machine operators can be greatly reduced. The simplicity in design also makes it easy for the operators to perform maintenance on the machine. Lower maintenance cost is a key advantage of using a POLYSTAR. The cost of consumable parts is 2.5~3 times lower comparing to European machine suppliers of similar built quality. POLYSTAR also keeps all critical components in stock to ensure fast spare parts delivery and minimize machine down time for its users. The delivery time of a key component such as a gearbox is within 7 days where as other machine suppliers could take 3~6 months in some occasions. POLYSTAR uses universal electrical components from Siemens and Schneider so that it’s easy for the users to source locally if required. Less waste generated – thanks to faster change between different types of materials. Professional recyclers often times have to change between different types of materials with different shapes and colors. POLYSTAR unique design has a much less change over time (up to 30~40%) during the “purging” process and therefore generate less production waste comparing to other recycling extruders. Both a single stage extruder and a two stage (cascade type) POLYSTAR extruder can adopt a FIMIC filter, with a production output range from 500kg ~ 1,000kg (1,100 ~2,200 pounds) per hour to select from. The FIMIC enhances the filtration performance whereas the POLYSTAR two stage extruder improves the degassing (gas removal) ability. | |

| Integration is simple and fast During the project preparation stage, POLYSTAR and FIMIC work very closely together with the customer for the customized build-up, providing each other with all the necessary details to ensure the extruder + filter integration is flawless. During the installation and start-up stage, technical engineers from both FIMIC and POLYSTAR will be present at the same time to assist customers and provide necessary trainings. “The set up was very easy” said Mr. Irvin, the Tennessee-based recycler in the US who installed the system in 2018 has been running the POLYSTAR + FIMIC recycling machine for the past two years, processing mainly coffee bean bags and peanut bags. “Their engineers came over for the set up, and in just 4 days we had the machine running already.” The recycler already plans to set up another line in 2021 as the business expands. Quoting a Rostov, Russia based recycler Europolimer who recently installed a second 750kg/hr two stage recycling line, “Both companies are already very experienced with this integration, they have done this for years and are familiar with each other’s equipment. We really benefited from this as it has worked very well for our plant,” according to Mr. Pavel, the production director of the Russian post-consumer recycler. “Both FIMIC and POLYSTAR focus on simplicity and low maintenance cost, we have been able to control our production cost well and stay competitive in the market.” In the case of a professional recycler located in Sweden, a FIMIC + POLYSTAR integration was even successfully done “remotely” due to recent travel restrictions and the effect of the COVID19 corona virus that prevent technicians from going overseas. “It is not a standard way,” said Mr. Peter of the Swedish recycler, “but the installation was successful! Big thanks to their team for the preparation and further action taken during the remote start-up and afterward to make it happen in this new way!” |

| |

| POLYSTAR Exhibition | |

| Find more info for How POLYSTAR assist your business at exhibition with Washed Flakes Recycling Machine | |

| |

|  |

| ||

| ||

TEL: +886-6-2730889 FAX: +886-6-2730887 WEB: www.polystarco.com E-MAIL: polystar.sales@gmail.com No.198, Ansin 2nd Rd., Annan Dist. Sinji Industrial Park. Tainan 709, Taiwan | ||

| ||

Stable Operation. Maximum performance. Minimum consumption POLYSTAR machines are powered by top quality electrical components Energy saving and high performance motors | ||

| Recommend Products | ||

|  | |

Two layer AB Blown Film Machine | Multilayer Blown Film Machine | Twin Head Blown Film Machine |

Possible Product | Possible Product | Possible Product |

| - LDPE, LLDPE Plastic Film - Mulch film - Agricultural film - Flexible packaging film - Carrier bags | - HDPE,LDPE, LLDPE Plastic Film - Flexible packaging bags - T-shirt bag - Garbage bag - Shopping bag | - Flexible packaging bags - T-shirt bag - Garbage bag - Shopping bag - Bottom sealed flat bag - Supermarket Bag |

Find more details on POLYSTAR Official Website: www.polystarco.com | ||

Taiwantrade.com and iDealEZ.com uses analytical cookies and other tracking technologies to offer you the best possible user experience. By using our website, you acknowledge and agree to our cookie policy.

For more information on cookies or changing your cookies settings, read Taiwantrade & iDealEZ’s Privacy Policy.