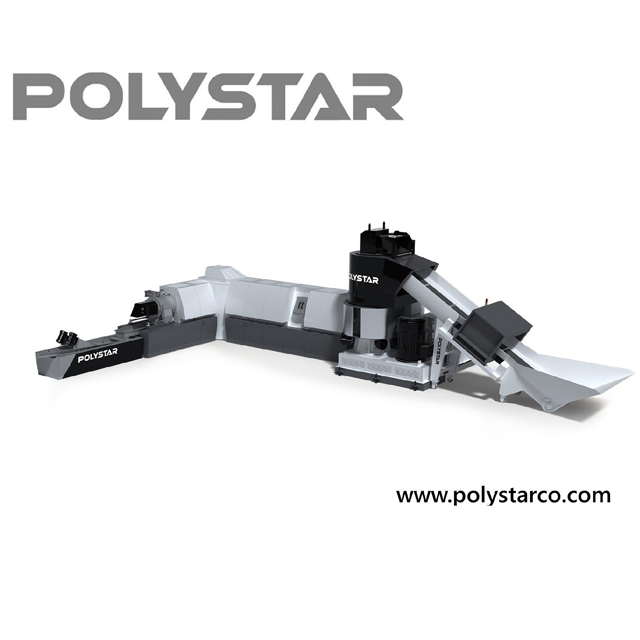

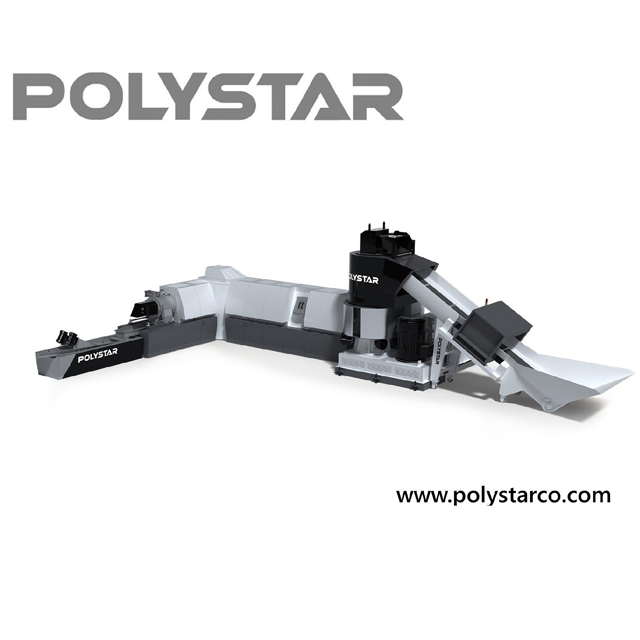

An improved design of the cutter compactor now works superbly with printed BOPP film. The compactor cuts, dries and compacts the material that enables a fast and stable feeding from the compactor directly into the extruder. Contact us if you are tempting!

❙ Product Description

The re-positioning of filtration before degassing ensures a superior degassing effect, producing excellent quality pellets from heavily printed material.

In addition to the double degassing in the first extruder, the venting area (the connection between the first and second extruder) serves as a third degassing section to further remove the ink and extra humidity level from the material.

An improved design of the cutter compactor now works superbly with printed BOPP film. The compactor cuts, dries and compacts the material that enables a fast and stable feeding from the compactor directly into the extruder.

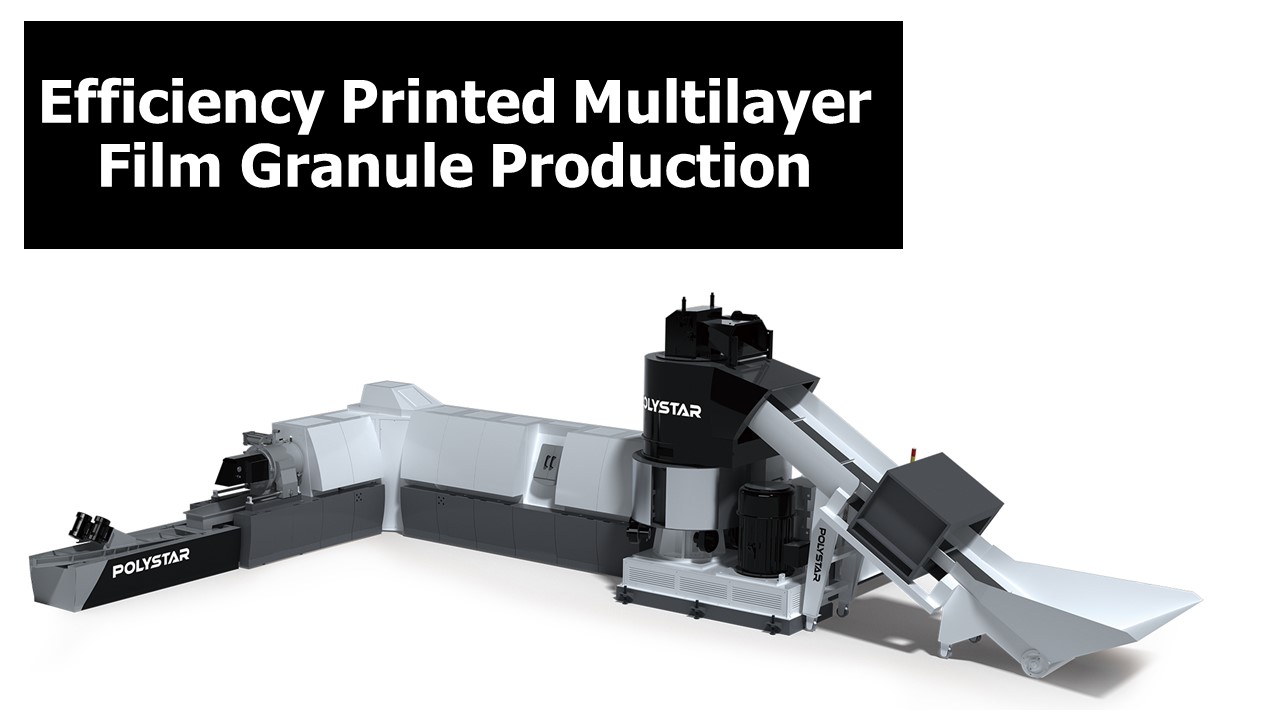

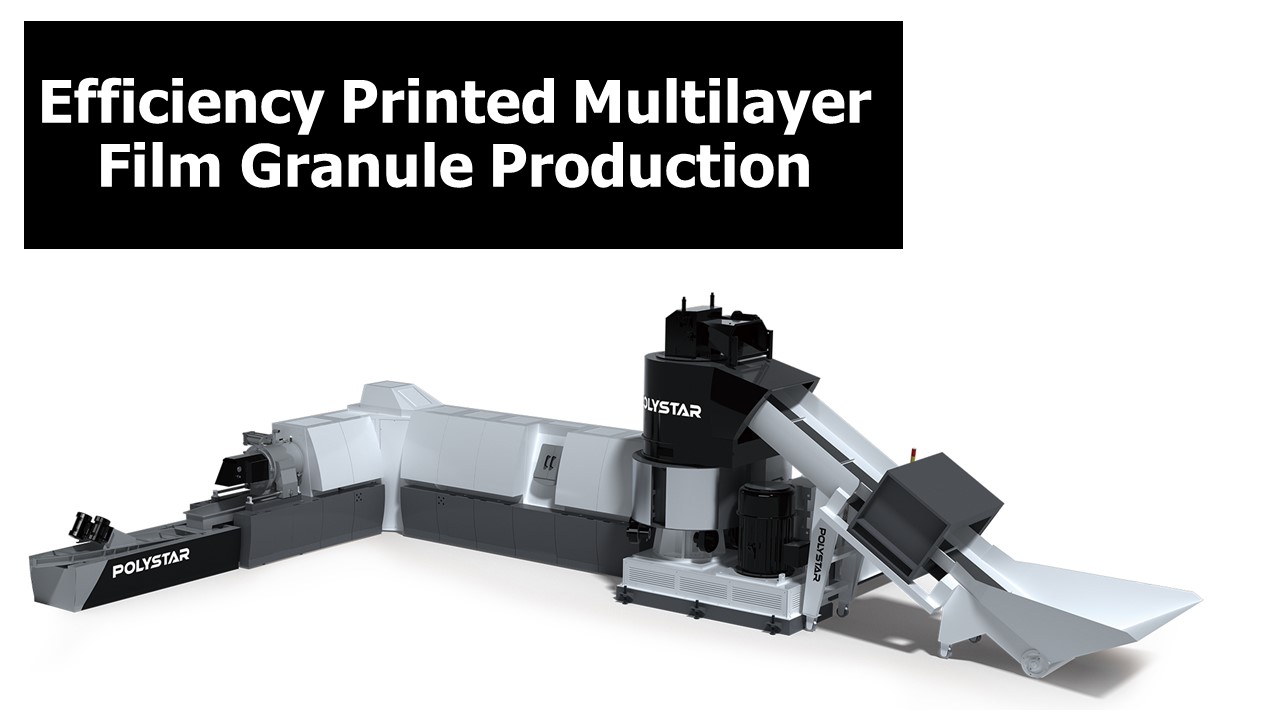

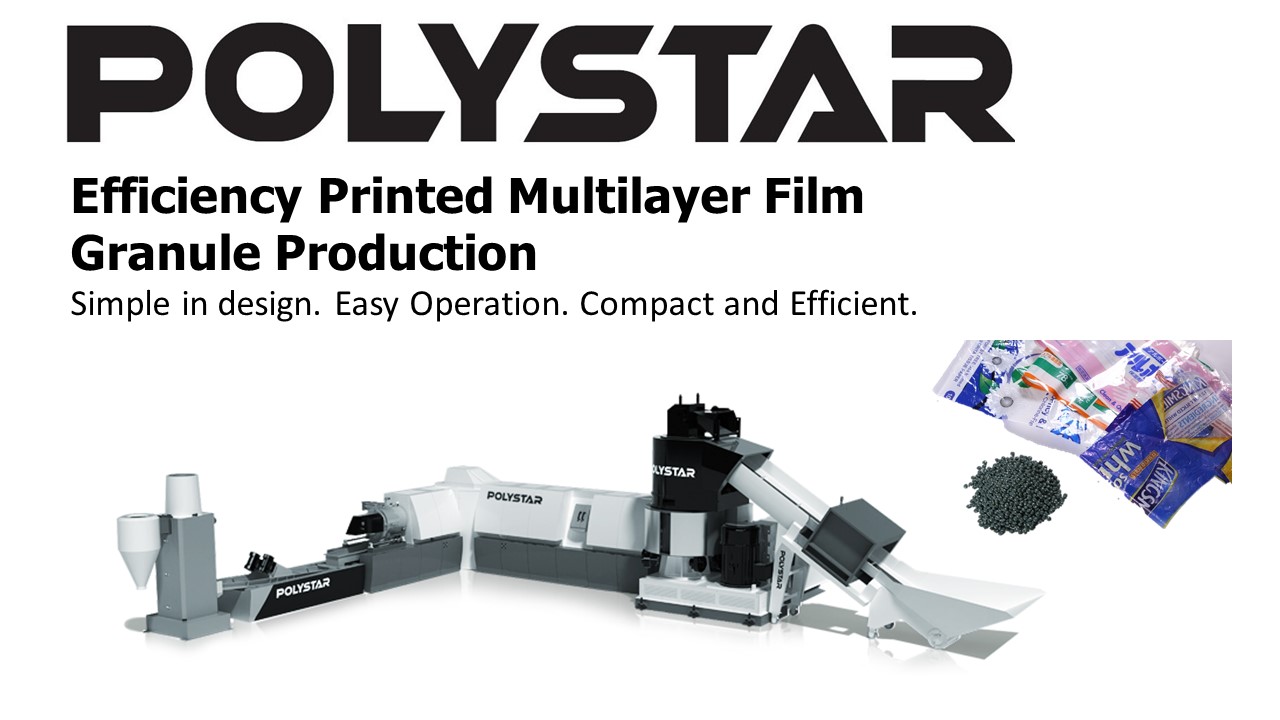

| Efficiency Printed Multilayer Film Granule Production |

- One-step direct technology with cutting + extrusion + pelletizing

- Very easy to install, operate and perform maintenance

- Our high-performance Printed Film Recycling System can help to provide better productivity and increased efficiency.

- Output : 100-1200kg/hr |

| Recycling Materials |

| Efficiency Printed Multilayer Film Granule Production |

|  |  |  |  |

Waste films | Printed film rolls | Food container | Non woven | PE/PP printed film rolls |

|  |  |  |  |

Printed waste bags | Humid prewashed flakes | Waste films | Stretch film | Printed Shrink Film |

|  |  |  |  |

Printed Woven sacks | Agricultural film | Printed Food packaging | Silk, tape, yarn, fiber | Printed Bubble film |

|  |  |  |  |

Humid Swimming pool covers | BOPP film | HDPE/PP Fabric | Foam sheet | Raffia |

| How Efficiency Printed Multilayer Film Granule Production work |

| 1 & 2 - Feeding

Feeding of scraps is easy, flexible and automatically controlled. Film-on rolls can be fed with nip roller feeder. The conveyor of Printed Film Recycling System is installed with sesotec metal detector made in Germany. |

|

| 3 - Cutting & Compacting

Very fast and stable feeding from the compactor directly into the extruder |

| 4 - Additive feeder

Color master batch and CaCO3 compounds (in pellet form) can be added during the recycling process |

| 5 - Double/Triple degassing (customized)

Able to process both printed and non-printed material |

| 6 - Filtration

Filter with dual channel system for non-stop operation and reduces machine down time |

| 7 - Die face pelletizing

Produces high quality plastic pellets for reprocessing |

Specifications |

| Efficiency Printed Multilayer Film Granule Production |

Model Name | Repro-Print

(Printed Multilayer Film Granule Production) |

Final Product | Plastic pellets/granule |

Machine Components | Conveyor belt, cutter compactor shredder, extruder, pelletizing unit, water cooling

unit, drying unit, silo tank |

Recycling Material | HDPE, LDPE, LLDPE, PP, BOPP |

Feeding | Conveyor belt |

Screw Material | SACM-465 |

Degassing | Double vented or triple degassing (customized) |

Cutting Type | Hot die face pelletizing |

Cooling | Water cooled |

Voltage | Customized |

Optional Devices | Metal detector(S+S) , Nip roller for film roll feeding , Additive feeder for masterbatch |

Warranty | 1 year |

Technical Assistance | Engineers available to service machinery overseas |

Successful Projects |

| Efficiency Printed Multilayer Film Granule Production |

|

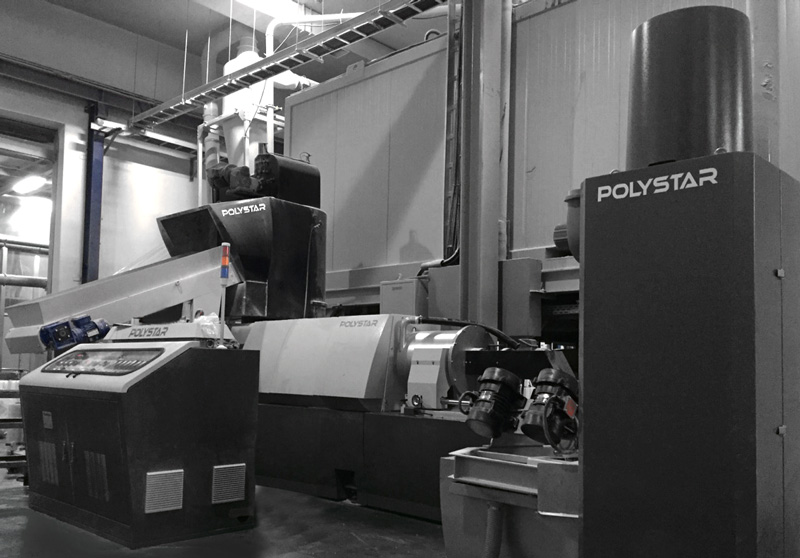

Leading PE stretch film producer in Taiwan Invests in POLYSTAR |

| As the largest LLDPE stretch and PE cling film producer in Taiwan with monthly production of 3,000 tons (achieved with several 5-layer cast film machines from Germany), in-house recycling is valued highly by the 30-year-old film producer as part of the production process to ensure quality and consistency in the end product remain high.

In 2016, the film producer has opted for the POLYSTAR Efficiency Printed Multilayer Film Granule Production to process its in-house waste generated from the extrusion lines. The POLYSTAR line was in fact the first equipment that the producer has ever purchased from an Asian manufacturer. Sharing his experience on the decision making process, the CEO was particularly impressed after seeing the trial runs at POLYSTAR’s facility, mainly for the following reasons:

- Simple operation and maintenance -

The increase in labor and logistics cost in Taiwan has become more difficult for Taiwanese plastic producers to stay competitive. Therefore making sure that minimal labor intervention on the machine is crucial.

- Consistency and quality in the recycled pellets -

The consistency in quality(uniform in size, reusability, minimal property change and degradation) of the recycled pellets can ensure that the recycled material can be reused again in the extrusion machines to produce high-end film product with the highest possible quality.

|

|  |

| The POLYSTAR Efficiency Printed Multilayer Film Granule Production is now running 24 hours a day and 7 days a week in the factory of the ISO 9002 certified film producer, with an average production of 250~300kg/hr with little operator intervention, setting another great example of effective and valuable in-house recycling.

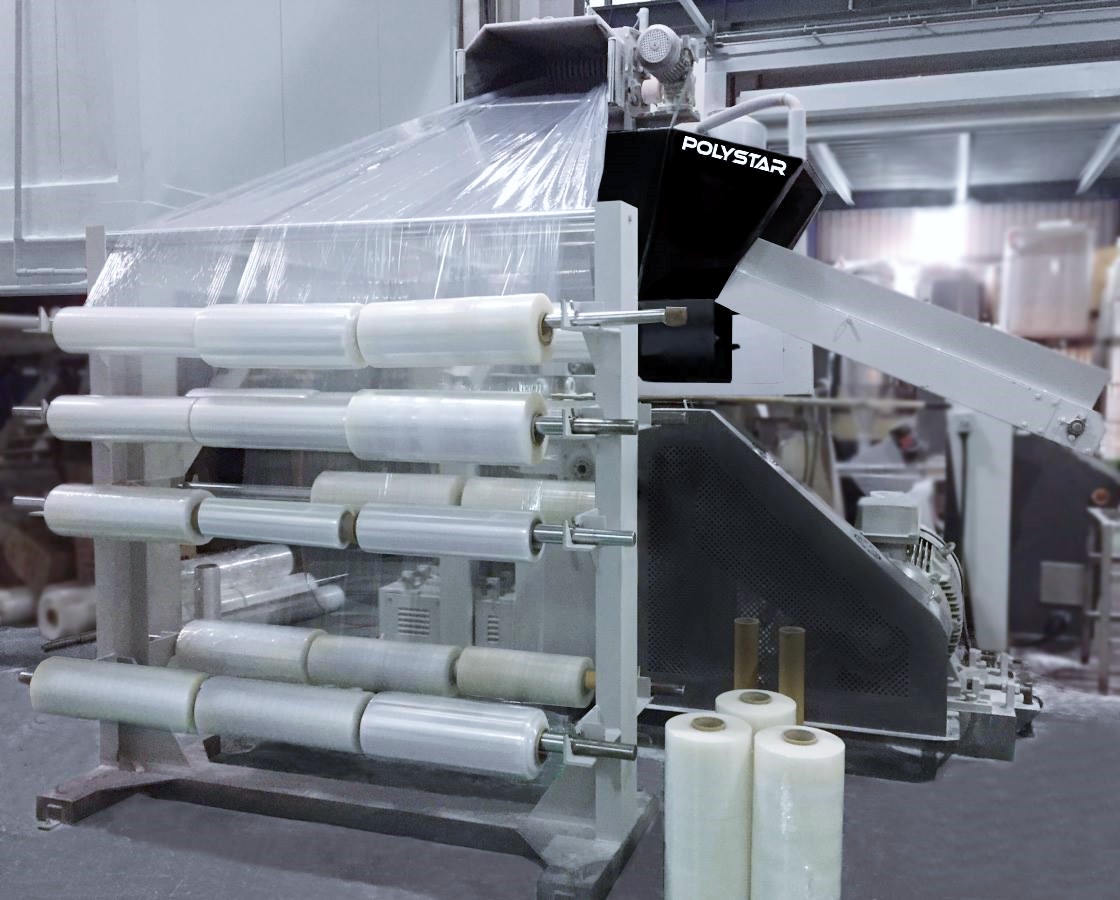

The defected film-on-rolls are fed automatically via the nip rolls on top of the cutter-compactor, which is then compacted and fed directly into the Efficiency Printed Multilayer Film Granule Production for further processing and pelletizing. The rest of the occasionally generated scraps are fed via the conveyor belt. The two-way feedings are controlled automatically and simultaneously to prevent over-feeding or insufficient feeding of material into the machine.

Despite the difference and variation in film width, thickness, layer structure (mono, three and five layers), the Efficiency Printed Multilayer Film Granule Production can handle all these film scraps of different compositions with consistency and still produce high quality and uniform-sized pellets, which are then put immediately back into the cast and stretch film lines.

|

|

Post-consumer recycling (PE/PP) growing in Russia

|

| Good degassing and filtration are probably the most important processes in pelletizing machines when it comes to post-consumer recycling. In many occasions, a Efficiency Printed Multilayer Film Granule Production is preferred by professional recyclers who focus on post-consumer recycling.

The washed material is fed into the compactor for a quick densifying process (which at the same time further dries the material by natural heat and friction); this helps to stabilize the material feeding into the extruder. The material then goes into the first (main) extruder for the filtration process and a two-vented degassing (installed with high efficiency vacuum system). The material then passes through an open area for the third and final degassing, and enters the second stage (short) extruder where the second filtering process is done.

The Efficiency Printed Multilayer Film Granule Production significantly improves the quality of the recycled pellets as the washed material goes through two filtration and three degassing steps in both extruders combined. As a result, the final pelletizing process becomes more stable and easier to operate because the material is already well prepared and pre-conditioned.

|

| A post-consumer recycler located in Belgorod, Russia who is dedicated in the recycling of municipal waste has a complete set up: The automatic sorting lines initially separate paper, glass, metal and plastic. The plastics are then separated by groups: 1) PET bottles, 2) films of HDPE and LDPE and 3) rigid plastic and followed by two washing lines - One for PET bottle and another for plastic films. After washing and drying the process is completed in the POLYSTAR Efficiency Printed Multilayer Film Granule Production. The recycled pellets are mainly used for producing plastic boxes for vegetables.

With strong know-how and service team from our local agent in Russia - Evropolimer, we can provide customers with the most suitable and simplest recycling solutions, followed by installation, training, spare parts and maintenance services.

|

| Company profile |

|

32 years of experience

Through years of manufacturing and designing experiences and continuous customer feedback, POLYSTAR has become one of the global leaders in the field through 3 generation of technological evolution.

A global leader with 4,180 machines installed

More than 4,180 machines have been installed since 1988. Proven success in Asia, Africa, Europe, Middle East & America.

Satisfied customers in 105 countries

POLYSTAR has been working closely with plastic producers around the world and has established itself as a premium brand that offers reliable and high performing machines in the market. |

|

| High quality recycled pellets

Up to 100% reusability back into your production line. Post-industrial waste generated from production of film, raffia and injection regrind can be recycled efficiently by Efficiency Printed Multilayer Film Granule Production and put right back into your production lines. Meaning less amount of new (raw) material needs to be used in your production. |

| Manufacturing with Precision

- CE certified Efficiency Printed Multilayer Film Granule Production with total quality control

- Adopts the latest design and manufacturing of screw and barrel to achieve maximum efficiency

- Strong research and design team |

| Service and Communication

- Overseas Efficiency Printed Multilayer Film Granule Production installation service and training are available

- Machine warranty with in-time spare parts delivery

- Fast online trouble shooting |

|

Film Production Industry |

|  |

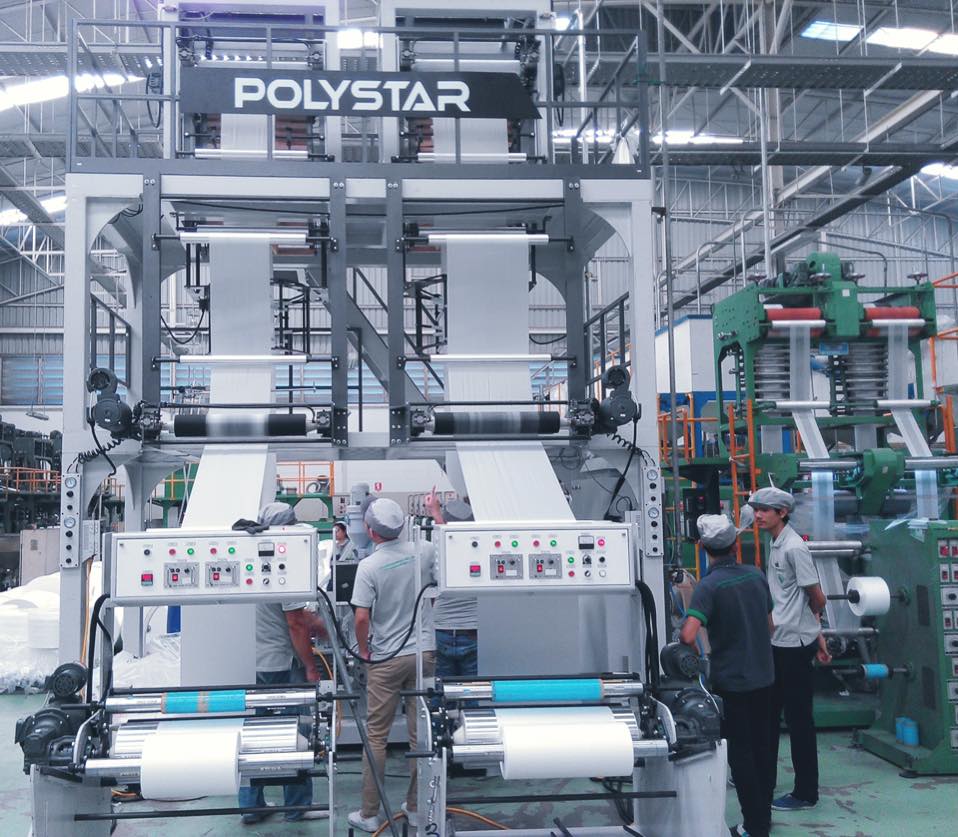

| T-shirt bag producer | Carrier and DHL bags |

Vietnam

The Vietnamese bag producer with monthly production of 1,500 tons doing 100% export to mainly European and Japanese markets.

HDPE thin T-shirt bags with virgin material for the Japanese market and LDPE thicker garbage bags (bag on rolls and draw tapes) with recycled material for the European markets can both be produced on the same DM55-750 machine.

The switch between producing HDPE/LDPE can be done simply by changing the die heads and air rings of the machines. Space saving, lower energy consumption, higher productivity are the reasons why the company continues to invest in POLYSTAR every year for both quality product and manufacturing efficiency. | UAE

Sharjah-based bag producer who manufactures LDPE two layer (AB) carrier bags, DHL bags, high quality shopping mall bag, soft loop handle and many others.

Load cell tension control, edge position control, 4 component gravimetric dosing and fully automatic double winding and cutting are equipped to improve manufacturing efficiency and automation.

Film thickness from 40 micron to 150 microns, and film width from 700 ~ 1300mm can be achieved in this machine depending on the product requirement. |

|

Recycling Industry |

|  |

| Thermoforming - PS, PP cups, trays producer | BOPP and laminated film producer |

Bolivia

Production waste from thermoformed PP trays, cups, spoons and PS utensils.

The largest plastic producer located in Bolivia with over 2,000 employees is currently recovering all of its industrial waste with two POLYSTAR recycling machine HNT-120V, processing in total of 1,000 kg/hour.

The recycling machine can flexibly handle both PP and PS thermoformed product, in addition to some of the PE and PP film waste. | Canada

BOPP and stretch film scraps and film on-roll can be turned into high quality pellets for reprocessing. POLYSTAR’s advanced cutter-compactor system can process material that is typically more difficult to recycle due to its special property, such as printed BOPP and stretch film that one normally faces problem with the traditional recycling systems. |

|

|

| POLYSTAR advantage |

| The design of the POLYSTAR pelletizing extruder is simple, and focused on the most important features for recyclers to have a stable operation in order to reduce down-time and lower production cost.

Easy operation

The emphasis on easy user-interface makes sure that the Initial training time and cost for (new) machine operators can be greatly reduced. The simplicity in design also makes it easy for the operators to perform maintenance on the machine.

Lower maintenance cost The cost of consumable parts is 2.5~3 times lower comparing to European machine suppliers of similar built quality.

Less waste generated – thanks to faster change between different types of materials. Professional recyclers often times have to change between different types of materials with different shapes and colors. POLYSTAR unique design has a much less change over time (up to 30~40%) during the “purging” process and therefore generate less production waste comparing to other recycling extruders. |

| POLYSTAR Exhibition |

| Find more info for How POLYSTAR assist your business at exhibition with Efficiency Printed Multilayer Film Granule Production |

|  |

|  |

|

|

Efficiency Printed Multilayer Film Granule Production

Official Website https://www.polystarco.com/tw/ products_i_Single_shaft_shredder.html

YouTube Channel:https://www.youtube.com /user/Polystarco

Facebook

|

|

Stable Operation. Maximum performance. Minimum consumption

POLYSTAR machines are powered by top quality electrical components

Energy saving and high performance motors |

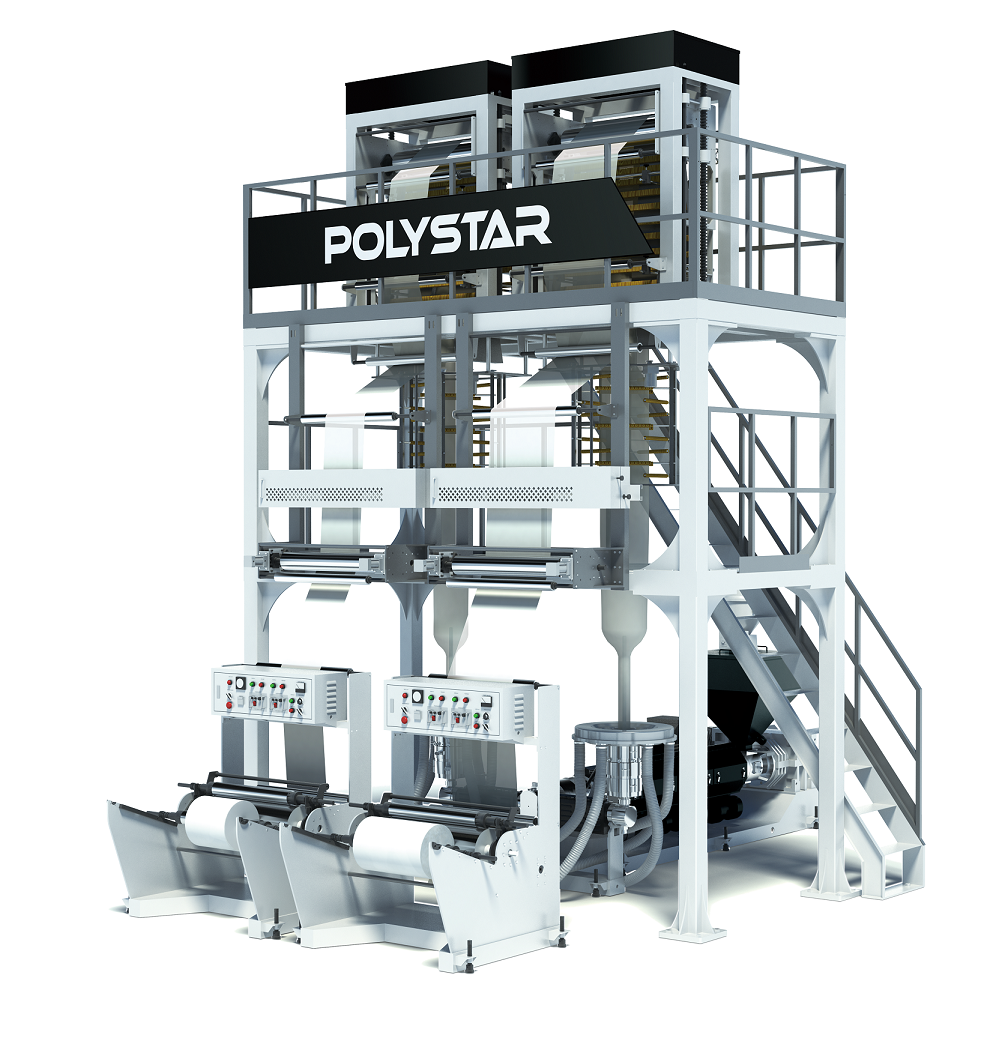

| Recommend Products |

|  |  |

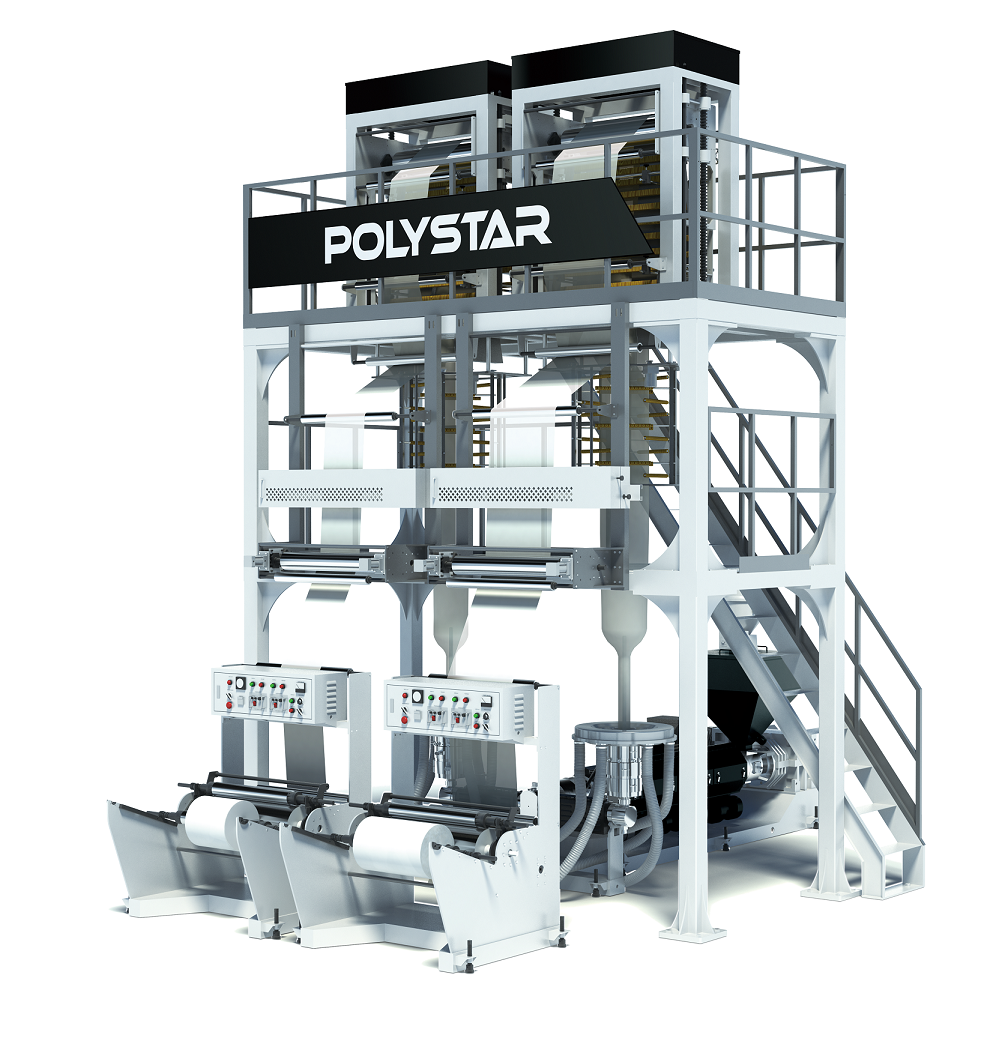

Two layer AB Blown Film Machine | Multilayer Blown Film Machine | Twin Head Blown Film Machine |

Possible Product | Possible Product | Possible Product |

- LDPE, LLDPE Plastic Film

- Mulch film

- Agricultural film

- Flexible packaging film

- Carrier bags | - HDPE,LDPE, LLDPE Plastic Film

- Flexible packaging bags

- T-shirt bag

- Garbage bag

- Shopping bag | - Flexible packaging bags

- T-shirt bag

- Garbage bag

- Shopping bag

- Bottom sealed flat bag- Supermarket Bag |

|