| Simple in Design. An Easier Way to Produce Quality |

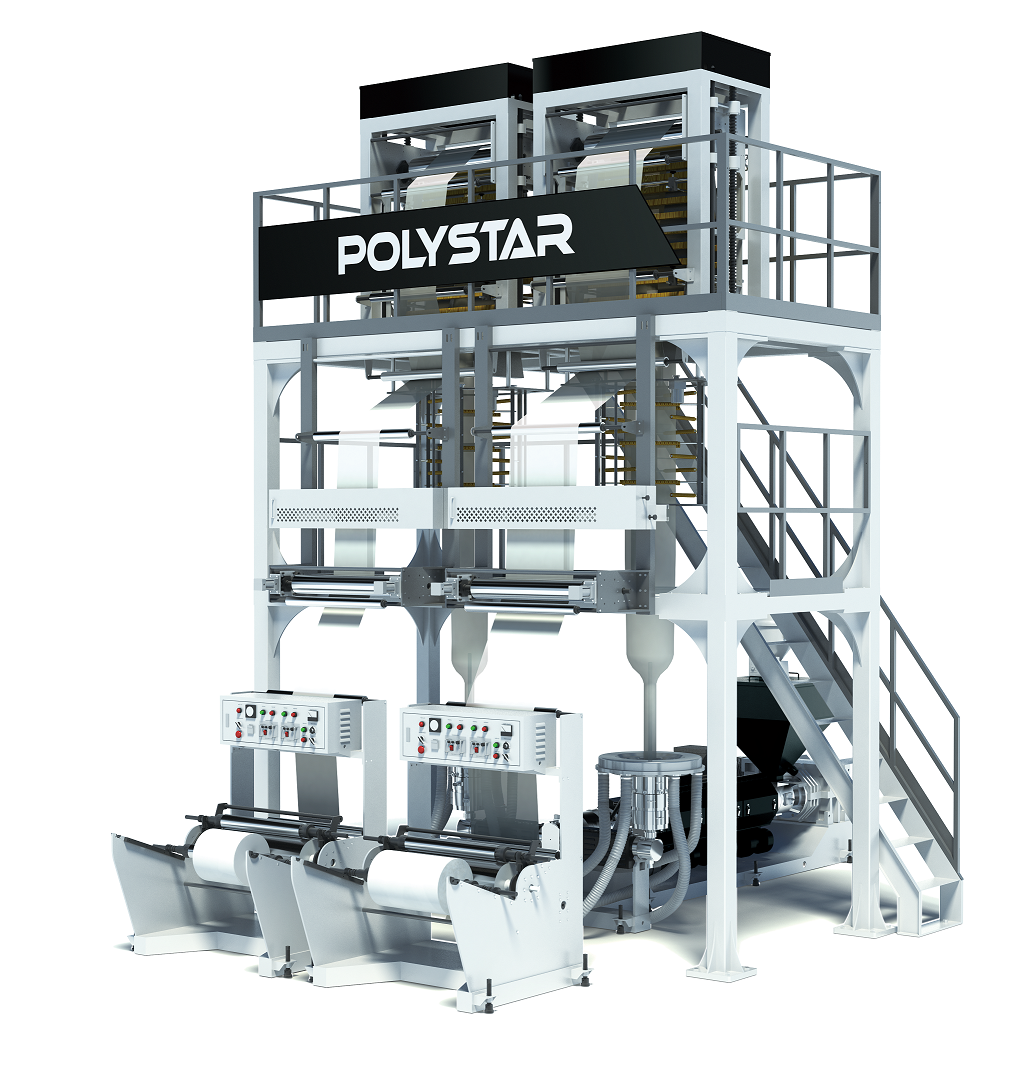

| Plastic Shrink Film Blowing Machine - Garbage bags (star-sealed, bag on-roll, draw string)- Industrial film of HDPE/LDPE/LLDPE - Better cooling effect for HDPE/LDPE/LLDPE, thicker film - Produce single layered sheet with back to back winder - Works with recycled material and CaCO3 |

Possible Product |

For Plastic Shrink Film Blowing Machine |

| ||||||

Model | Width (mm) | Thickness (mm) | Output (kg/hr) | |||

HDPE | LDPE | HDPE | LDPE | |||

| HA55 (HA55-1200) | 300-1100 | 0.008-0.03 (8-30 micron) | 0.02-0.1 (20-100 micron) | 65-85 | 75-95 | |

| HA65 (HA65-1500) | 400-1350 | 85-110 | 100-140 | |||

| HA75 (HA75-1800) | 500-1600 | 100-130 | 120-160 | |||

| Product info | |

| Of Plastic Shrink Film Blowing Machine | |

| |

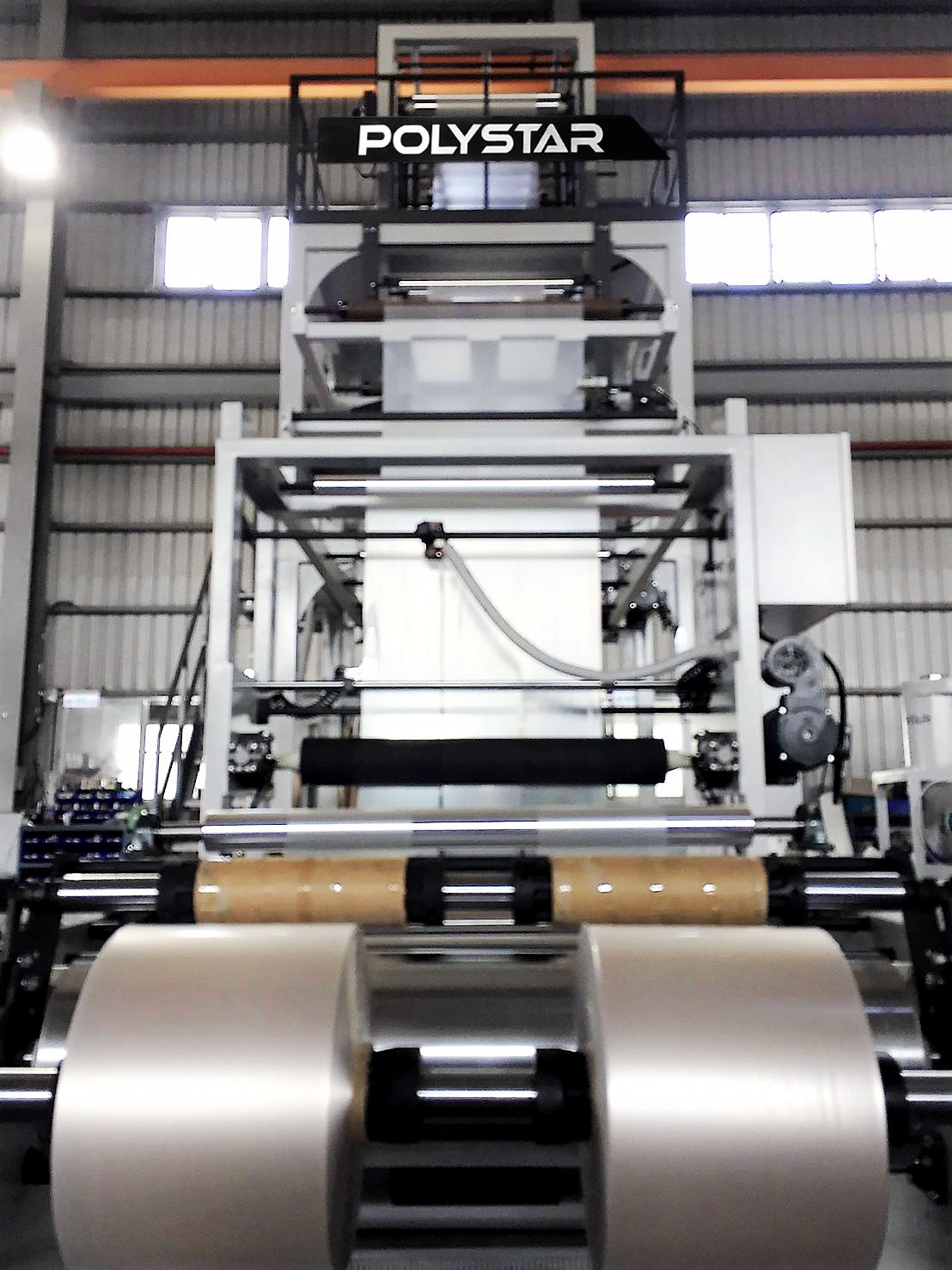

| Plastic Shrink Film Blowing Machine provides a good solution for general packaging and produces quality film. Suitable for general packaging products such as T-shirt bags, supermarket bags, flat bags and many others. Plastic Shrink Film Blowing Machine's film width available from 800 mm to 2300 mm and can be customized depending on customer's requirement, suitable for both HDPE, LDPE and LLDPE film. | |

| |

| The specially designed Plastic Shrink Film Blowing Machine has good ability for melting and mixing material with master batch /additives. | |

| Plastic Shrink Film Blowing Machine Plastic Shrink Film Blowing Machine is a simple and flexible machine that can produce HDPE or LDPE, by simply changing the die head and air ring. |

| Double Winding Plastic Shrink Film Blowing Machine Double winding unit, manual or automatic type can be added for single-layer film for lamination.Back-to Back or Top-Down types are available depending on customer's factory space and layout. | |

Plastic Shrink Film Blowing Machine in customer's plant | |

| |

| Plastic bag producer | |

Vietnam Product: Garbage bags (draw tape) Material: Recycled with Calcium carbonate (CaCO3) Country: Vietnam Model: Star-X 65-1400 Current capacity in total: 1,700 tones/month Number of POLYSTAR machines: 22 Main reason for choosing this model: To increase film strength for draw-tape garbage bag production with 3 layer. Also, to add more recycled material in the middle (B) layer. Machine configuration: Rotating die head. Co-extrusion ABA die head for both HDPE and LDPE. | |

|  |

| Packaging industry | |

USA Product: Shrink film Material: Metallocene + LDPE Model: Star-X 55-1200 blown film extrusion machine Current capacity in total: 600 tones/month Number of POLYSTAR machines: 1 Machine configuration: special die head design for shrink film, rotary die device, edge position control, back to back double winder, hot slitting knife | Indonesia Product: Ice bags Material: LDPE Model: Star-X 55-1200 blown film extrusion machine Current capacity in total: 1,200 tones/month Number of POLYSTAR machines: 10 Machine configuration: rotary die device, back to back double winder |

POLYSTAR Exhibition | |

With Plastic Shrink Film Blowing Machine | |

| |

|  |

Why POLYSTAR Plastic Shrink Film Blowing Machine | |||||||

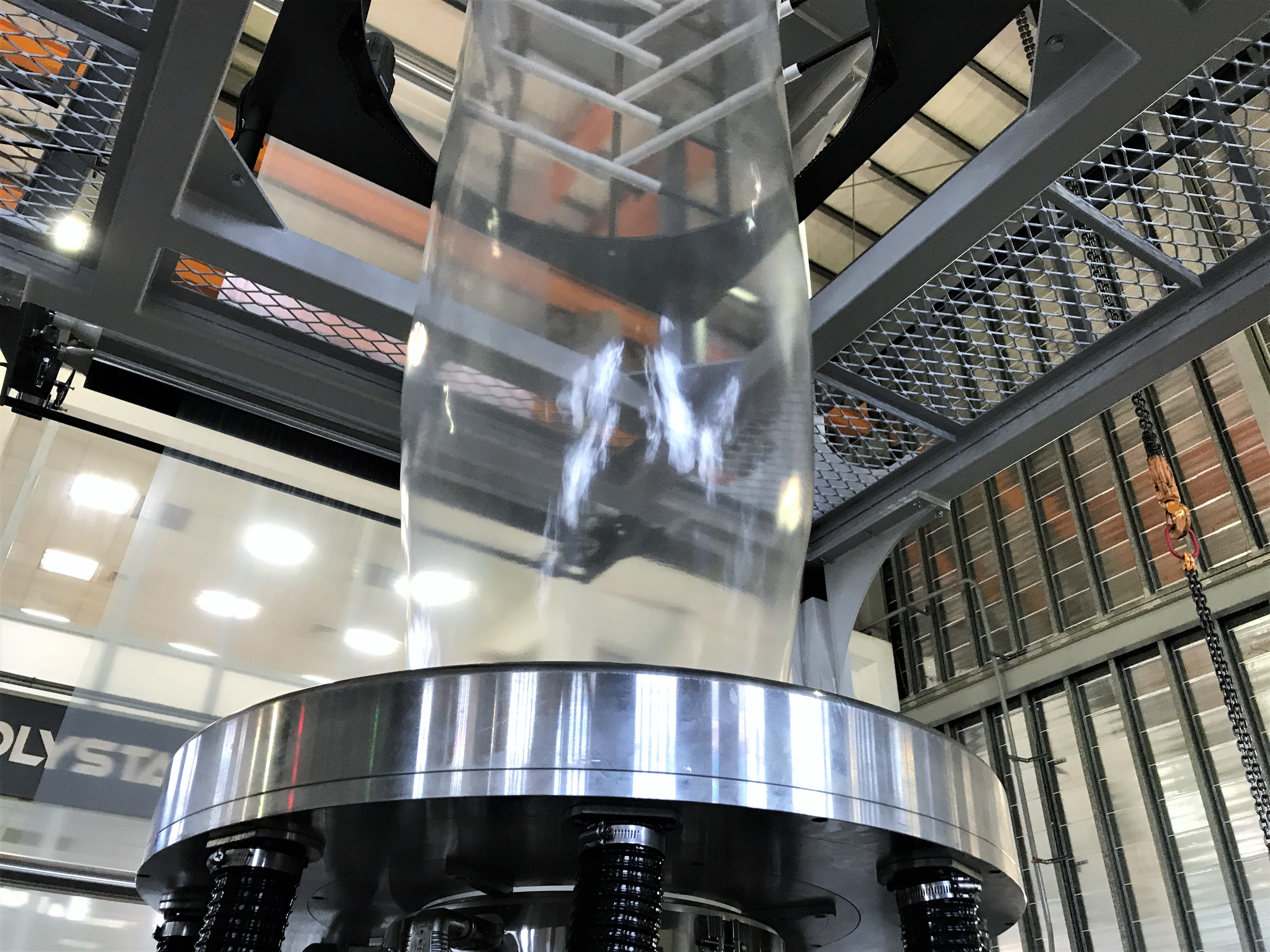

High quality film roll

| |||||||

| Manufacturing with Precision

| ||||||

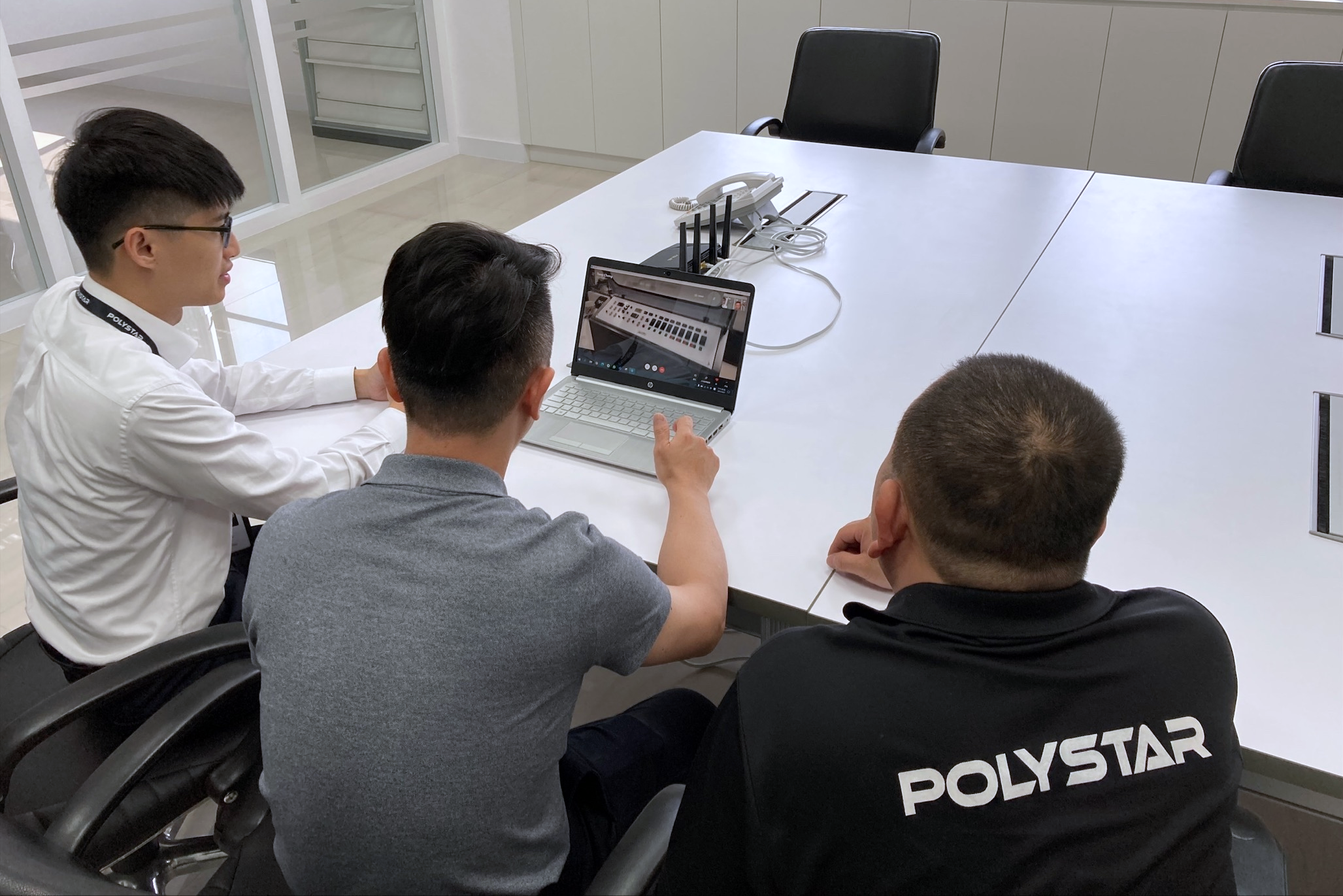

| Service and Communication Overseas

| ||||||

| Shipping photos | |||||||

| Plastic Shrink Film Blowing Machine | |||||||

| |||||||

| Recommend products | ||

|  |  |

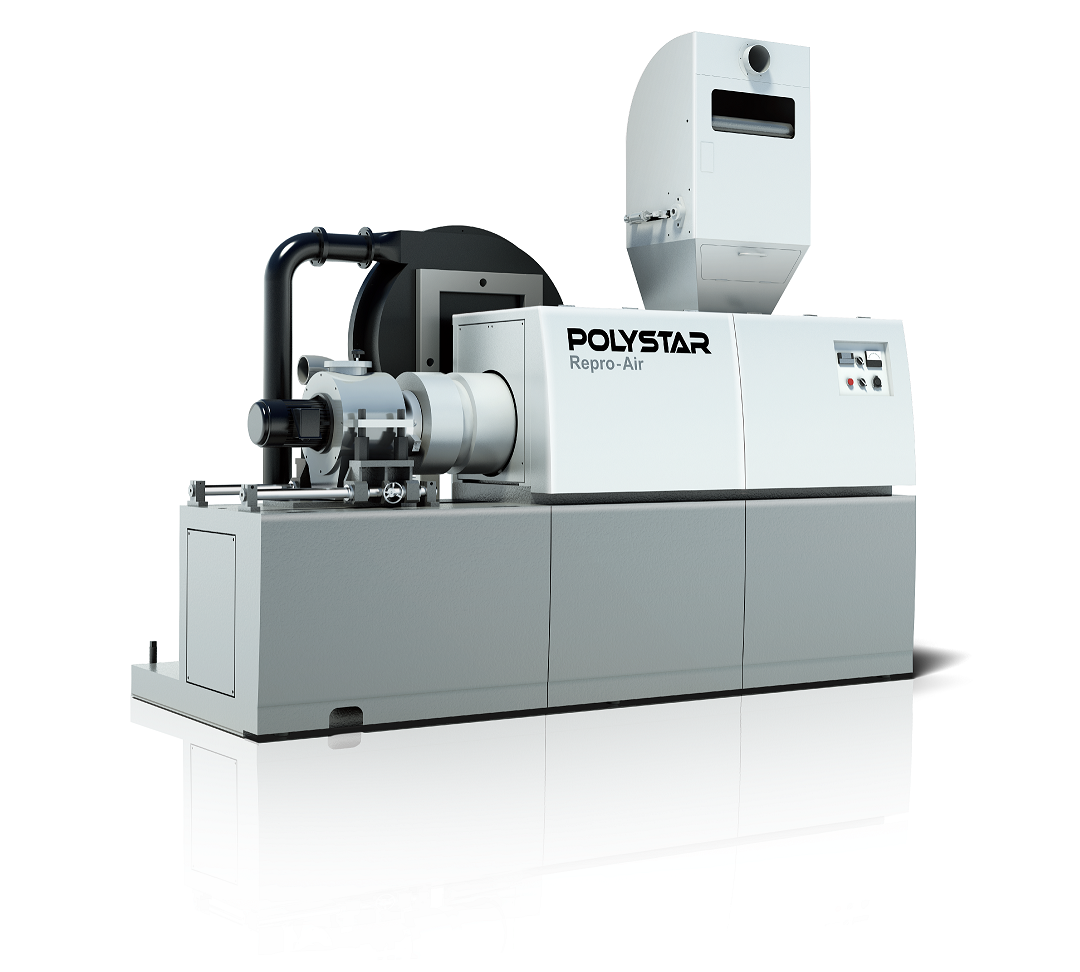

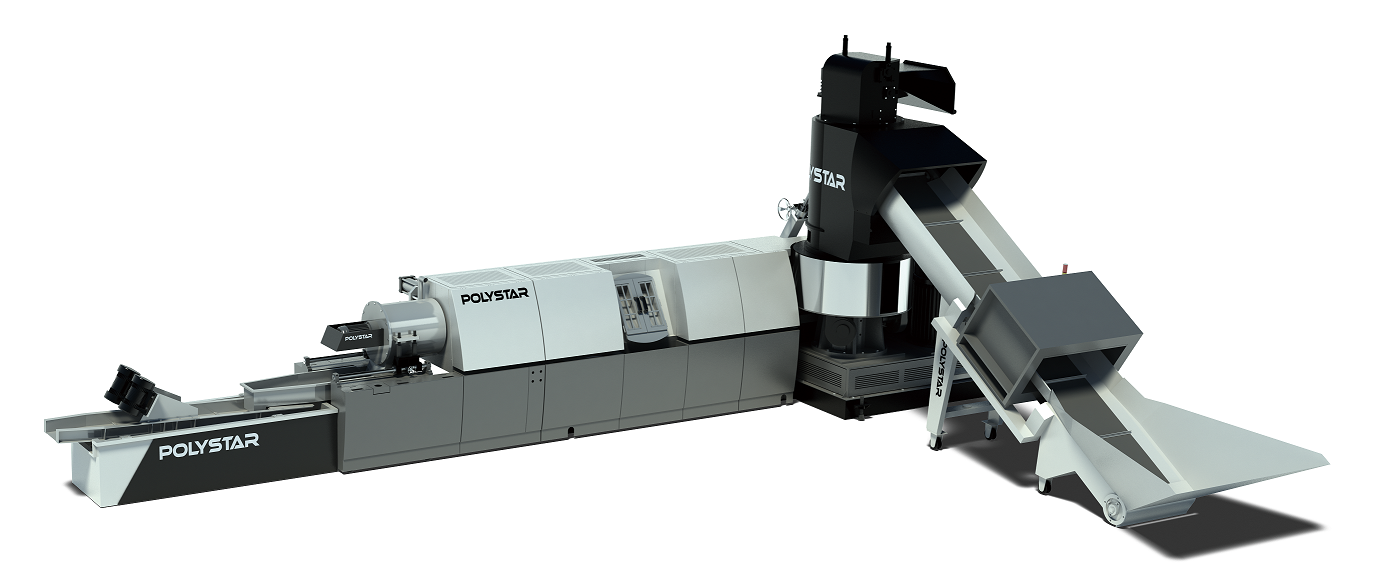

| Twin head blown film machine | Air cooled recycling machine | Plastic film recycling machine |

Are you from the EU regions?

Taiwantrade.com and iDealEZ.com uses analytical cookies and other tracking technologies to offer you the best possible user experience. By using our website, you acknowledge and agree to our cookie policy.

For more information on cookies or changing your cookies settings, read Taiwantrade & iDealEZ’s Privacy Policy.