Plastic Shredder Integrated Recycling Machine eliminates the need of pre-cutting/pre-shredding large-sized, thick or bulky waste, feeding the waste directly from the shredder into the extruder at a very fast and constant rate without over-heating the material. Do not hesitate to contact us!

❙ Product Description

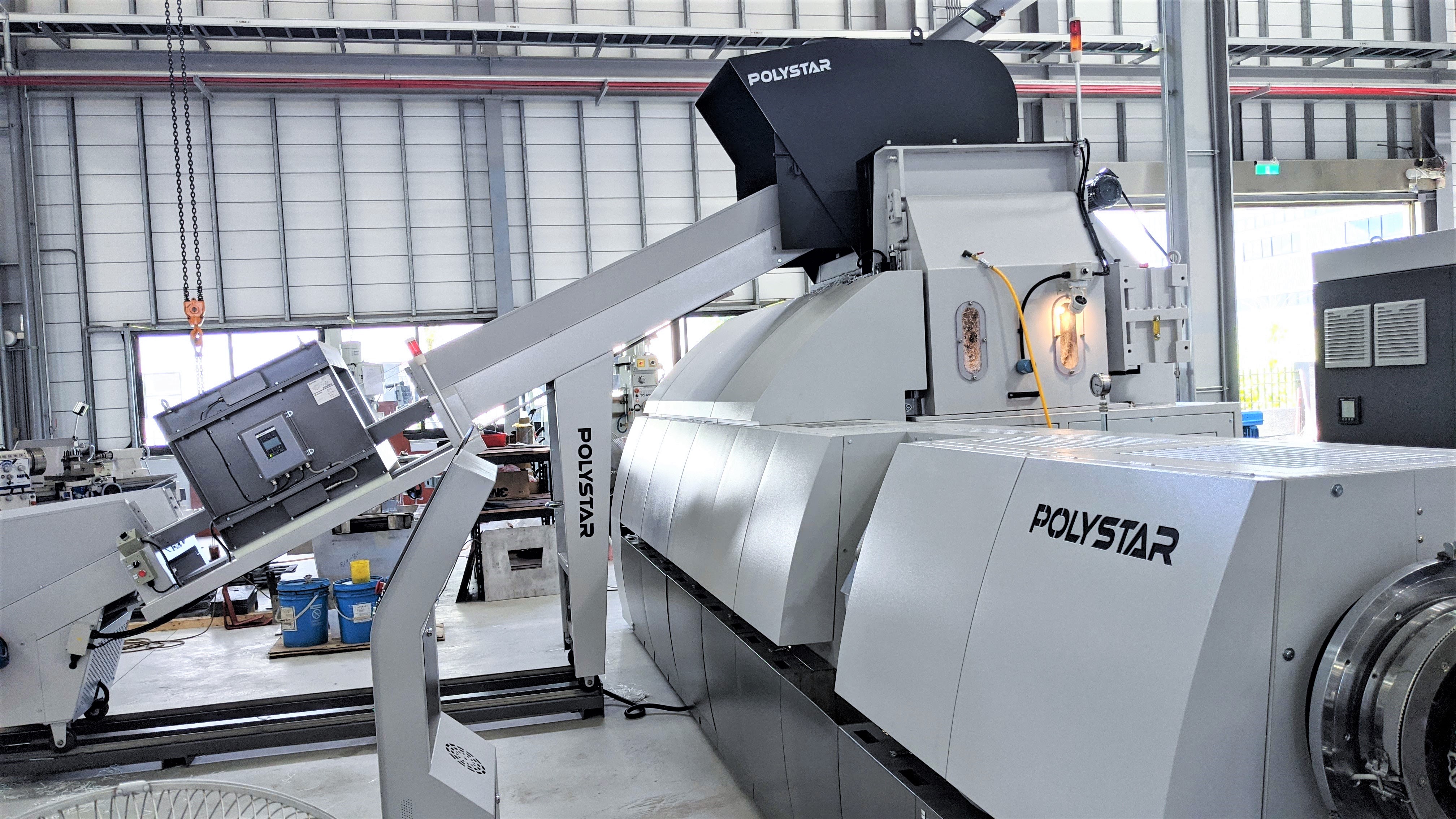

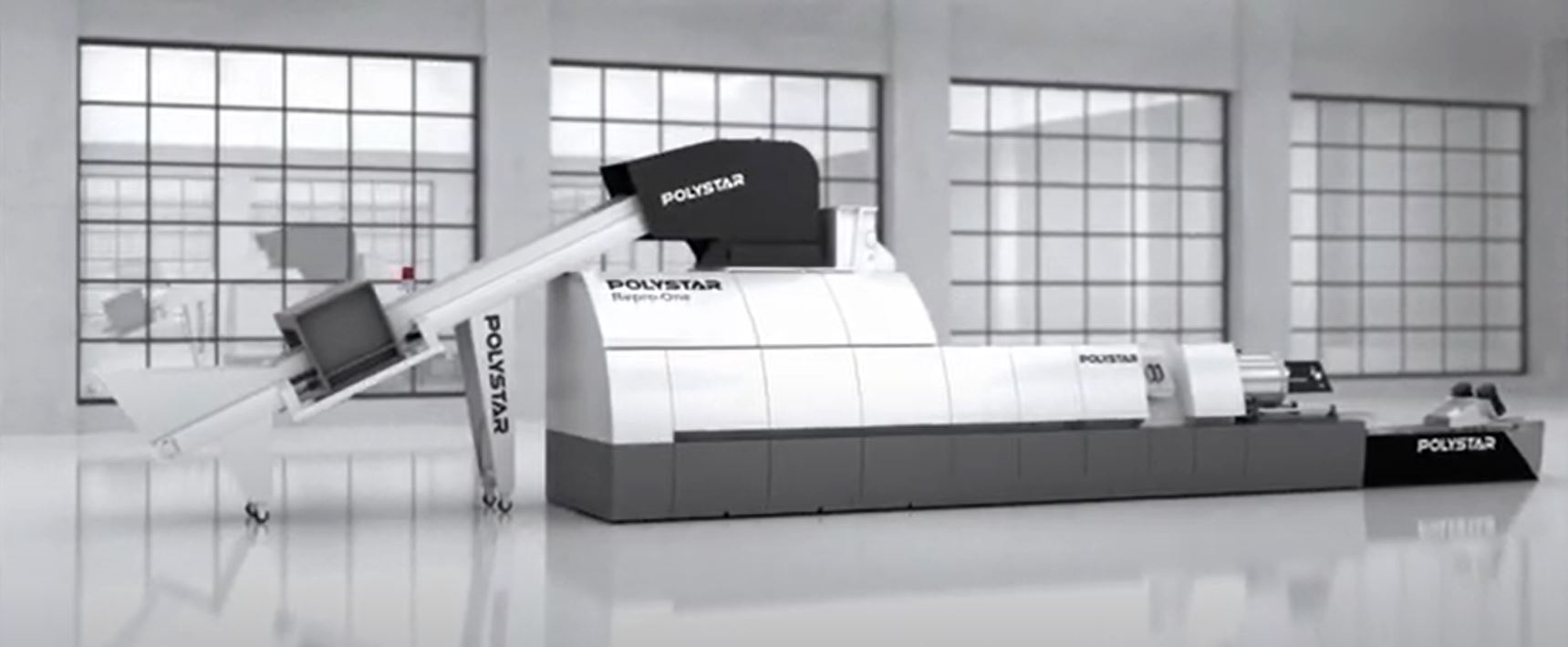

Plastic Shredder Integrated Recycling Machine has an integration of a heavy duty single-shaft shredder that is directly connected with the extruder pelletizer.

The recycling machine is ideal for PP raffia/PP non-woven manufacturer who process their rejected raffia waste (tapes, fabric, jumbo big bags, lumps) generated from in-house production. The recycled pellets can be put directly back into tape extrusion lines for immediate reprocessing. These recycled pellets can be loaded in high percentages and still produce excellent fabric with good tensile strength and elongation.

This eliminates the need of pre-cutting/pre-shredding large-sized, thick or bulky waste (including hard plastics), feeding the waste directly from the shredder into the extruder at a very fast and constant rate without over-heating the material. This technology ensures continuous and uniform feeding to the extruder that produces high quality recycled pellets.

The precisely controlled ram inside the shredder continuously pushes the bulky material towards the rotating shredder. After shredding, the material is fed directly into the extruder. The material then goes through degassing (if the material is printed) and filtered before the die face pelletizing process. The Large-sized Waste Shredder Integrated Granulation Line can effectively process large-sized waste such as jumbo bags, raffia, tape, woven and nonwoven without pre-shredding in advance.

The flexibility of the Plastic Shredder Integrated Recycling Machine allows raffia and film producers to reprocess their in-house production waste easily in a single machine. The high quality pellets with minimal material degradation can be reused 100% in reprocessing which generates great secondary values for the producers.

| Large-sized Waste Shredder Integrated Granulation Line |

One step technology for PP raffia, woven and PE/PP film waste |

- High percent of recycled pellets back into your tape and film extrusion lines- One-Step, simple process

- Large-sized, hard-to-crushed waste

- Material of different shapes and sizes - No need to pre-crushed |

| Model Comparision |

| Large-sized Waste Shredder Integrated Granulation Line |

|

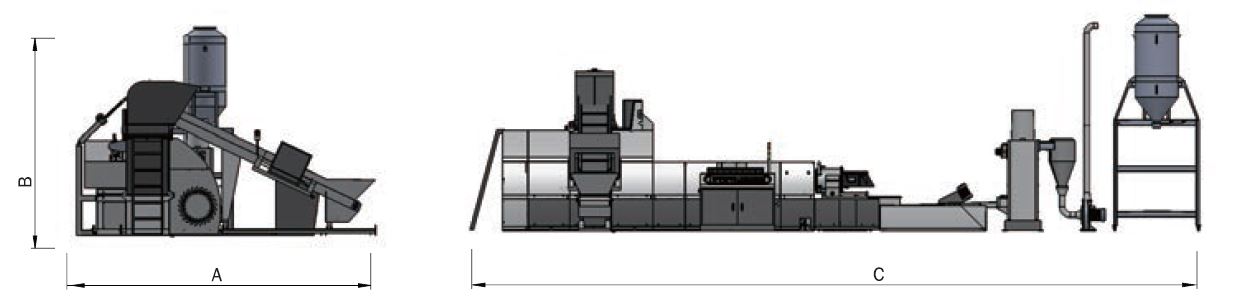

Model | *Output range (kg/hr) | Power consumption | Dimension |

A(Length) | B(Height) | C(Width) |

Repro-One 65

| 80-110 | 55 kw | 5800 | 4100 | 11300 |

Repro-One 85

| 150-250 | 95 kw | 5900 | 4100 | 12000 |

Repro-One 100

| 250-350 | 138 kw | 6000 | 4100 | 12700 |

Repro-One 120

| 350-500 | 153 kw | 6100 | 4100 | 13400 |

* The machine layout (picture) is for reference only. The actual layout changes depending on the optional devices (metal detector, centrifugal dryer, nip roll feeder, venting option, filter option and machine cover option) that the customer chooses.

* Output based on clean, dry LDPE film processing without degassing. |

| Recycling Material |

| Large-sized Waste Shredder Integrated Granulation Line |

|  |  |  |  |

Film roll/scraps | Raffia | Jumbo Bag | Woven Sack | Bottles / Hard Plastic |

|  |  |  |  |

PP ropes | Plastic lumps | PP non woven bag | PP woven bag | Bulks |

Large-sized Waste Shredder Integrated Recycling Facility is ideal for PP raffia/PP non-woven manufacturer who process their rejected raffia waste (tapes, fabric, jumbo big bags, lumps) generated from in-house production.

|

| Product Description |

| Large-sized Waste Shredder Integrated Granulation Line |

One-step process with lowest material degradation

The one step Large-sized Waste Shredder Integrated Granulation Line Repro-One has an integration of a heavy duty single-shaft shredder that is directly connected with the extruder pelletizer. |

|

| Ideal for both raffia and film waste

The recycling machine is ideal for PP raffia/PP non-woven manufacturer who process their rejected raffia waste (tapes, fabric, jumbo big bags, lumps) generated from in-house production. The recycled pellets can be put directly back into tape extrusion lines for immediate reprocessing. These recycled pellets can be loaded in high percentages and still produce excellent fabric with good tensile strength and elongation. |

Directly processes, uniform feeding

This eliminates the need of pre-cutting/pre-shredding large-sized, thick or bulky waste (including hard plastics), feeding the waste directly from the shredder into the extruder at a very fast and constant rate without over-heating the material. This technology ensures continuous and uniform feeding to the extruder that produces high quality recycled pellets. |  |

| Simple operation, high performance recycling machine

The precisely controlled ram inside the shredder continuously pushes the bulky material towards the rotating shredder. After shredding, the material is fed directly into the extruder. The material then goes through degassing (if the material is printed) and filtered before the die face pelletizing process. The Large-sized Waste Shredder Integrated Granulation Line can effectively process large-sized waste such as jumbo bags, raffia, tape, woven and nonwoven without pre-shredding in advance. |

|

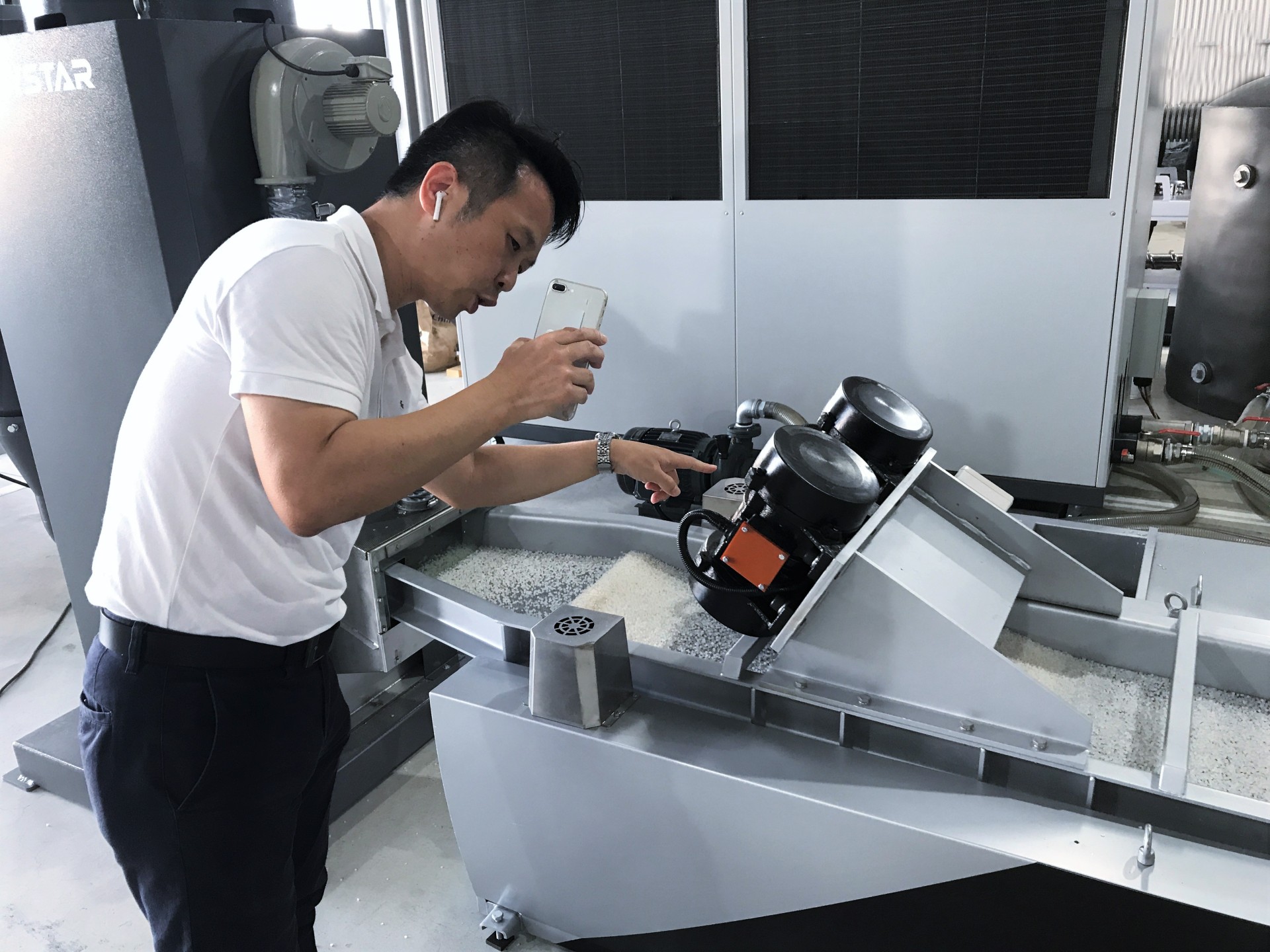

100% reusable recycled pellets

The flexibility of the Repro-One Large-sized Waste Shredder Integrated Granulation Line allows raffia and film producers to reprocess their in-house production waste easily in a single machine. The high quality pellets with minimal material degradation can be reused 100% in reprocessing which generates great secondary values for the producers. |

|

| Customers' photo |

| Large-sized Waste Shredder Integrated Granulation Line in customs' plant |

|  |

Recycle in an easy way - Work with POLYSTAR!

- Simple solutions for processing film, raffia, injection, foam and washed film waste

- Small to big production output range available depending on your requirement

- Simple machine operation and maintenance

- Easy spare parts replacement

- Highest quality of in-house recycling, achieved in an easy way

- Flexible machine design to meet your requirement and factory layout |

| Worldwide presence |

|

| World-class Producer of Plastic Recycling Machine |

- More than 4,180 machines have been installed since 1988

- Satisfied customers in 105 countries in Asia, Africa, Europe, Middle East & America

- Cooperates with small, medium-sized companies to industrial leaders

- 170 Recycling machines have been sold to date since K show (Germany) in 2016

- More than 300% growth in revenue since 2013 |

| Recycle in an easy way - Work with POLYSTAR! |

|  |  |

High quality recycled pellets | Manufacturing with Precision | Service and Communication |

| Up to 100% reusability back into your production line. Post-industrial waste generated from production of film, raffia and injection regrind can be recycled efficiently by Large-sized Waste Shredder Integrated Granulation Line and put right back into your production lines. Meaning less amount of new (raw) material needs to be used in your production. | - CE certified Large-sized Waste Shredder Integrated Granulation Line with total quality control

- Adopts the latest design and manufacturing of screw and barrel to achieve maximum efficiency

- Strong research and design team | - Overseas Large-sized Waste Shredder Integrated Granulation Line installation service and training are available

- Machine warranty with in-time spare parts delivery

- Fast online trouble shooting |

|

| POLYSTAR Exhibition with |

| Large-sized Waste Shredder Integrated Granulation Line |

|  |

|  |

| Shipment |

| Large-sized Waste Shredder Integrated Granulation Line |

|  |

| Contact POLYSTAR |

| Large-sized Waste Shredder Integrated Granulation Line

Official Website:https://www.polystarco.com/tw/products_i_Single_shaft _shredder.html

Youtube Channel:

https://www.youtube.com/user/Polystarco

Email:

polystar.sales@gmail.com

Contact Number:

+886 6 273 0889

Address:

No.198, Ansin 2nd Rd., Annan Dist. Sinji Industrial Park. Tainan City 709, Taiwan |

|

|

|

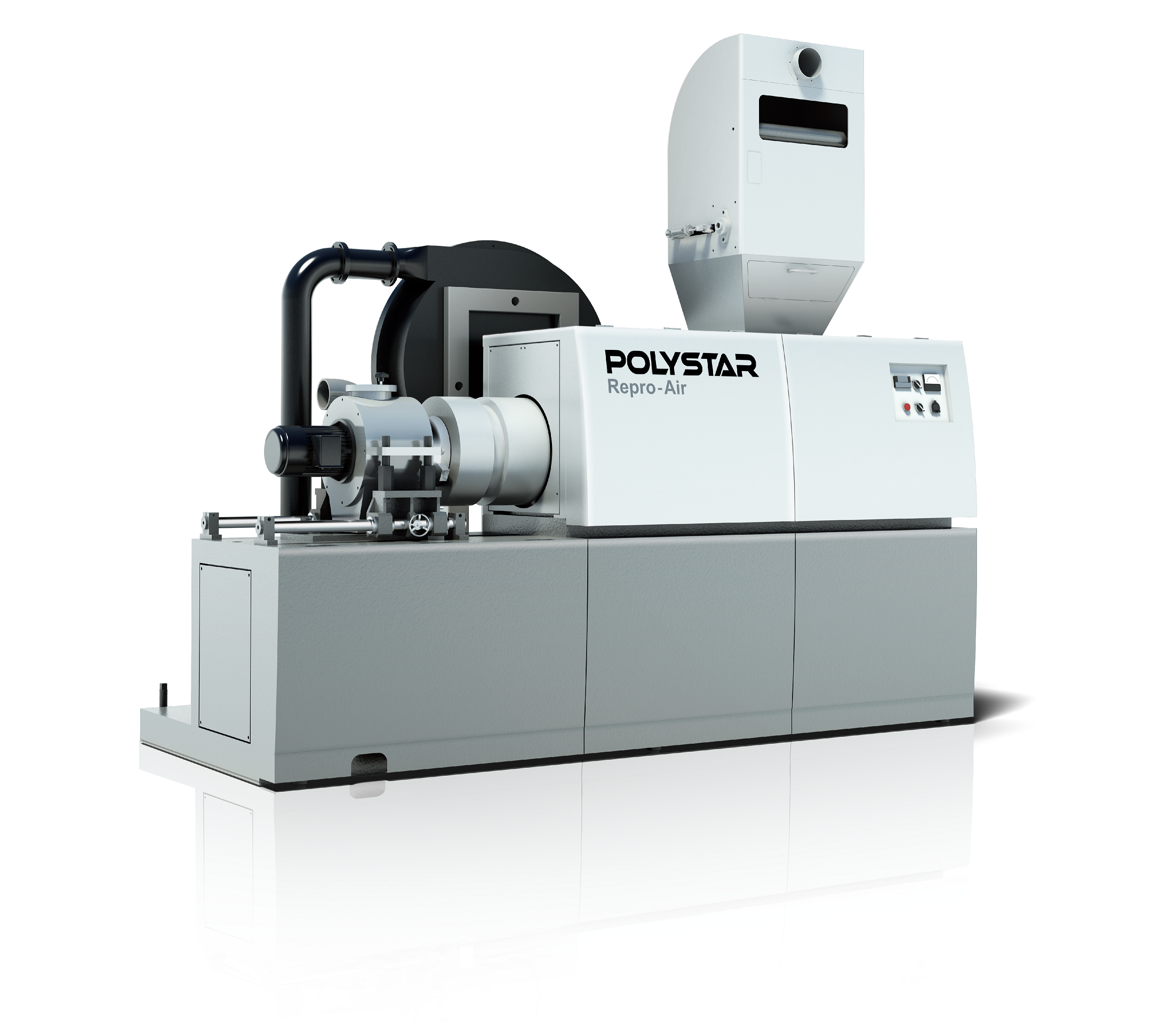

| Recommend products |

|  |  |

Air cooled recycling machine | Multilayer Blown Film Machine | Twin Head Blown Film Machine |

Recycling Materials | Possible Product | Possible Product |

-In-house plastic waste, Film rolls, T-shirt bag cut-offs, flat bags, commercial bags, garbage bags, food packaging film, shrink

film | - HDPE,LDPE, LLDPE Plastic Film

- Flexible packaging bags, T-shirt bag, garbage bag, shopping bag | - Flexible packaging bags- T-shirt bag, garbage bag, shopping bag

- Bottom sealed flat bag- Supermarket Bag

|