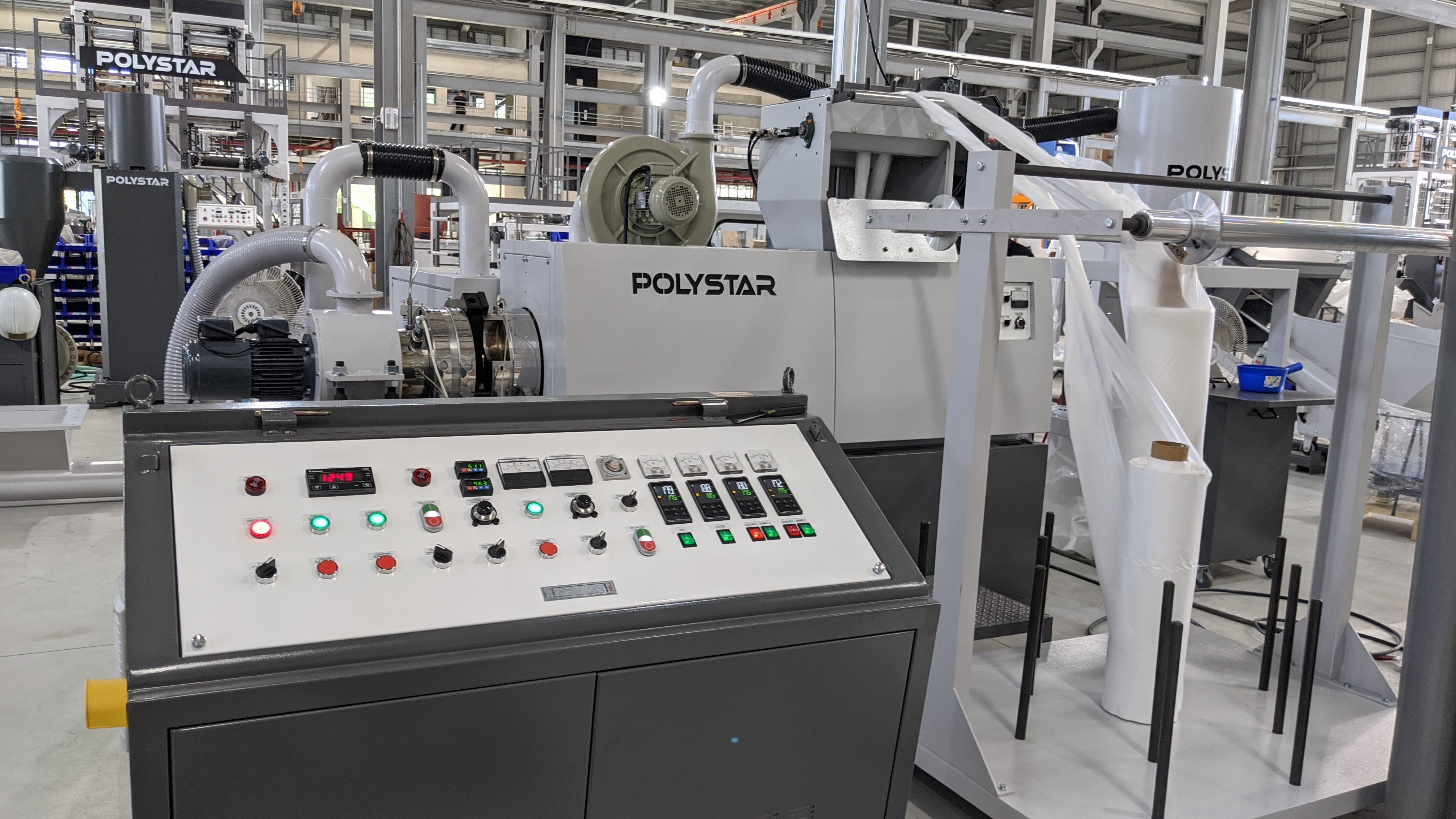

Leno bags Small Air-cooled Plastic Recycling Machine is specially designed for blown film and cast film producers. Leno bags Small Air-cooled Plastic Recycling Machine can effectively recycle HDPE, LDPE, LLDPE film scraps (mono and multi-layer), start-up or changeover film rolls (film-on-roll), edge-trim waste, T-shirt bag bundles (cut- offs) from in-house production. lightly-printed film can also be recycled into high quality, uniformed pellets by Small air-cooled plastic recycling. | |

Leno bags Small Air-cooled Plastic Recycling Machine does not require any water consumption and takes up very little space, it can fit right next to or in between blown film machines. The pellets produced by the hot die face pelletizer are 100% dry and can be put directly back into the production line for immediate reprocessing. Leno bags Small Air-cooled Plastic Recycling Machine is highly recommended for packaging film producers of different types of film and bags. | |

The compact design of the recycling machine is ideal for producers with limited factory space. Leno bags Small Air-cooled Plastic Recycling Machine dimension (length x width x height) is 2.5M x 2.5M x 2 M. It is extremely compact and user-friendly, and does not require any installation (ready-to use) upon Leno bags Small Air-cooled Plastic Recycling Machine arrival. |

High quality recycled pellets High quality recycled pellets

|

Manufacturing with Precision Manufacturing with Precision

|

Service and Communication Service and Communication

|

Our Experience, Your Advantage  |

POLYSTAR Exhbition with Leno bags Small Air-cooled Plastic Recycling Machine

|

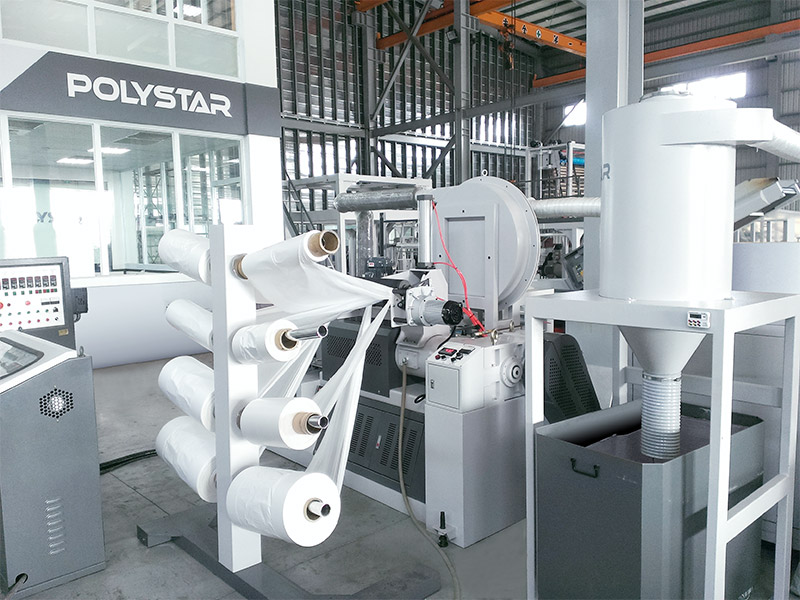

Sri Lanka – Second Repro-Air installed In September, Polystar installed another Leno bags Small Air-cooled Plastic Recycling Machine for the Sri Lankan film producers. The result is high quality recycled pellets. In addition, low maintenance requirement and processing stability of the Leno bags Small Air-cooled Plastic Recycling Machine is the reason why the Colombo-based film producer decided to add its second Polystar with less than one year after the first installation. Significant reduces cost This compact, Leno bags Small Air-cooled Plastic Recycling Machine is specially designed for blown film and cast film producers. The model can effectively recycle HDPE and LDPE film scraps, start-up or changeover film rolls (film-on-roll) without the need for pre-cutting, edge-trim waste, T-shirt bag bundles (cut- offs) from in-house production. Lightly-printed film can also be recycled into high quality, uniformed pellets. According to the film producers located in Colombo, Sri Lanka, the recycled pellets from the Polystar recycling machines are reused 100% in their blown film process. “We decided to go with Polystar because our experience with the company has been superb.” The film producer is now able to recycle almost all of its production waste to make pellets with excellent quality, from HDPE film scraps to LDPE film-on-roll– and considerably increase the percentage of recycled pellets in the end product (film). The advantage of this is higher production efficiency and with reduction in production costs. Saving space and water The space-saving recycling machine Repro-Air (economic type - RP120) plastic recycling machine has an average output of 30~80kg per hour, 800~1000kg per day. Through the nip roll feeder, the recycling machine can process multiple film rolls simultaneously. T-shirt bag bundles (cut-offs) from bag making process can also be thrown directly into the recycling machine without the need for pre-crushing. This Leno bags Small Air-cooled Plastic Recycling Machine does not require any water consumption and takes up very little space, it can fit right next to or in between blown film machines. The pellets produced by the hot die face pelletizer are 100% dry and can be put directly back into the production line for immediate reprocessing. This plastic recycling machine is highly recommended for packaging film producers of different types of film and bags, such as flat bags, commercial bags, garbage bags, food packaging film, shrink film and many others. Working principles The space-saving plastic recycling machine Repro-Air (economic type - RP120) has an average output of 30~80kg per hour, 800~1000kg per day. Through the nip roll feeder, the machine can process multiple film rolls simultaneously with a precise control of material instake. T-shirt bag punches (cut-offs) from bag making process can also be put directly into the recycling machine without the need for pre-crushing. After the hot die-face cutting, the air-cooled pellets are transported into a spiral device for further pellet cooling and separation. This special design allows the machine to effectively pelletize HDPE and LDPE with minimal material property change. The compact design of the recycling machine is ideal for producers with limited factory space. The machine dimension (length x width x height) is 2.5M x 2.5M x 2 M. It is extremely compact and user-friendly, and does not require any installation (ready-to use) upon machine arrival. The average lead-time of a Polystar air-cooled recycling machine is only 60 days. |

| Leno bags Small Air-cooled Plastic Recycling Machine Find more info on POLYSTAR Website: www.polystarco.com |

Are you from the EU regions?

Taiwantrade.com and iDealEZ.com uses analytical cookies and other tracking technologies to offer you the best possible user experience. By using our website, you acknowledge and agree to our cookie policy.

For more information on cookies or changing your cookies settings, read Taiwantrade & iDealEZ’s Privacy Policy.