| Company profile |

|

34 years of experience

Through years of manufacturing and designing experiences and continuous customer feedback, POLYSTAR has become one of the global leaders in the field through 3 generation of technological evolution.

A global leader with 4,180 machines installed

More than 4,180 machines have been installed since 1988. Proven success in Asia, Africa, Europe, Middle East & America.

Satisfied customers in 105 countries

POLYSTAR has been working closely with plastic producers around the world and has established itself as a premium brand that offers reliable and high performing machines in the market. |

|

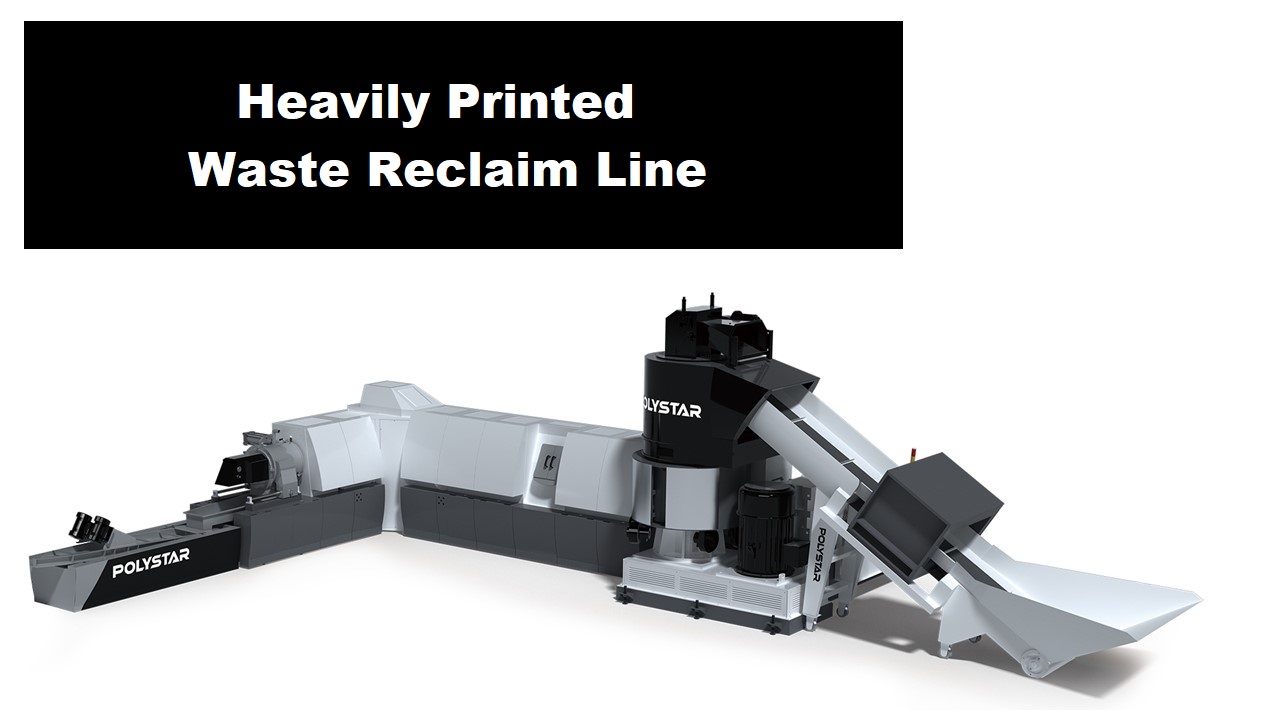

| High quality recycled pellets

Up to 100% reusability back into your production line. Post-industrial waste generated from production of film, raffia and injection regrind can be recycled efficiently by Heavily Printed Waste Reclaim Line and put right back into your production lines. Meaning less amount of new (raw) material needs to be used in your production. |

| Manufacturing with Precision

- CE certified Heavily Printed Waste Reclaim Line with total quality control

- Adopts the latest design and manufacturing of screw and barrel to achieve maximum efficiency

- Strong research and design team |

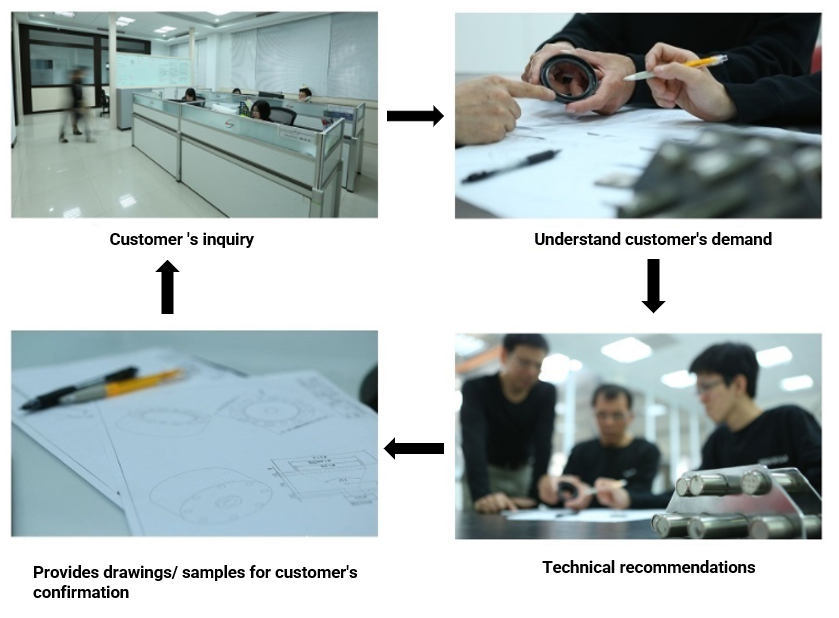

| Service and Communication

- Overseas Heavily Printed Waste Reclaim Line installation service and training are available

- Machine warranty with in-time spare parts delivery

- Fast online trouble shooting |

|

Film Production Industry |

|  |

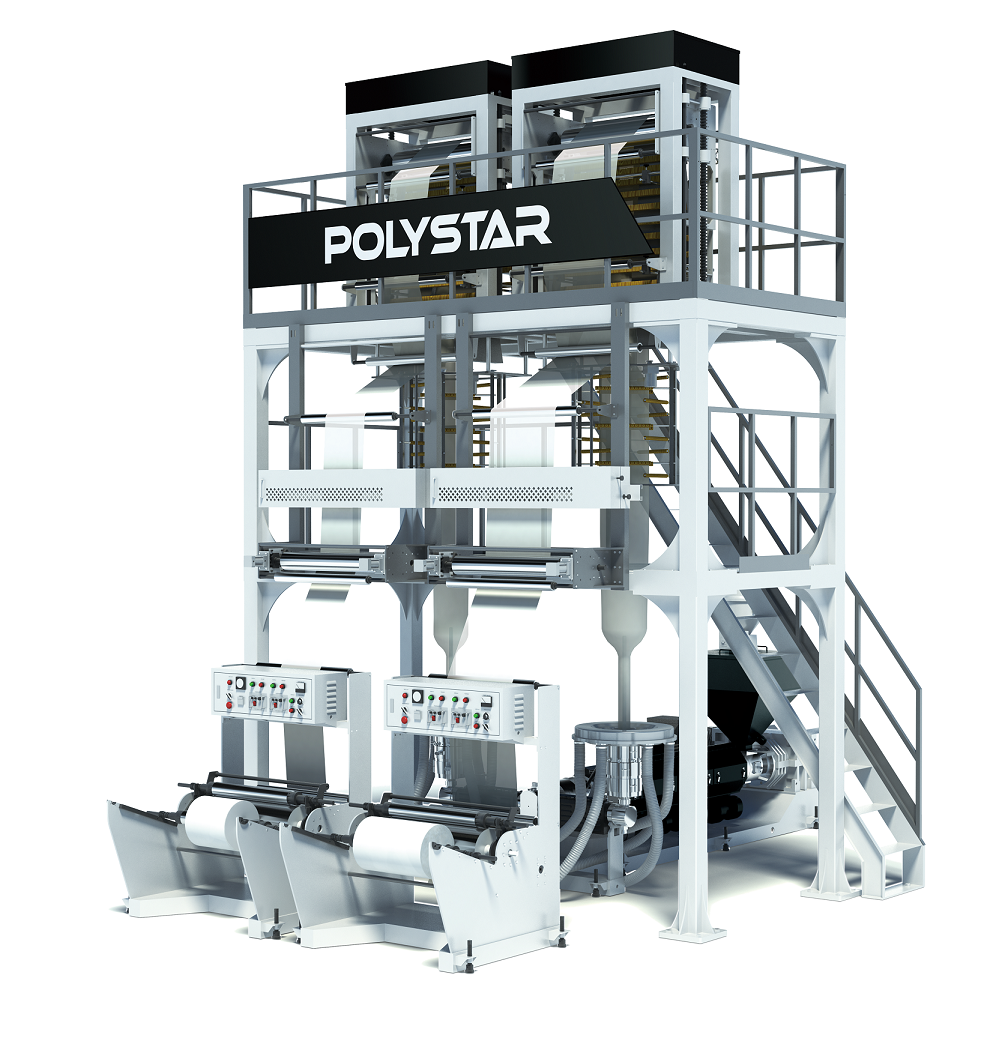

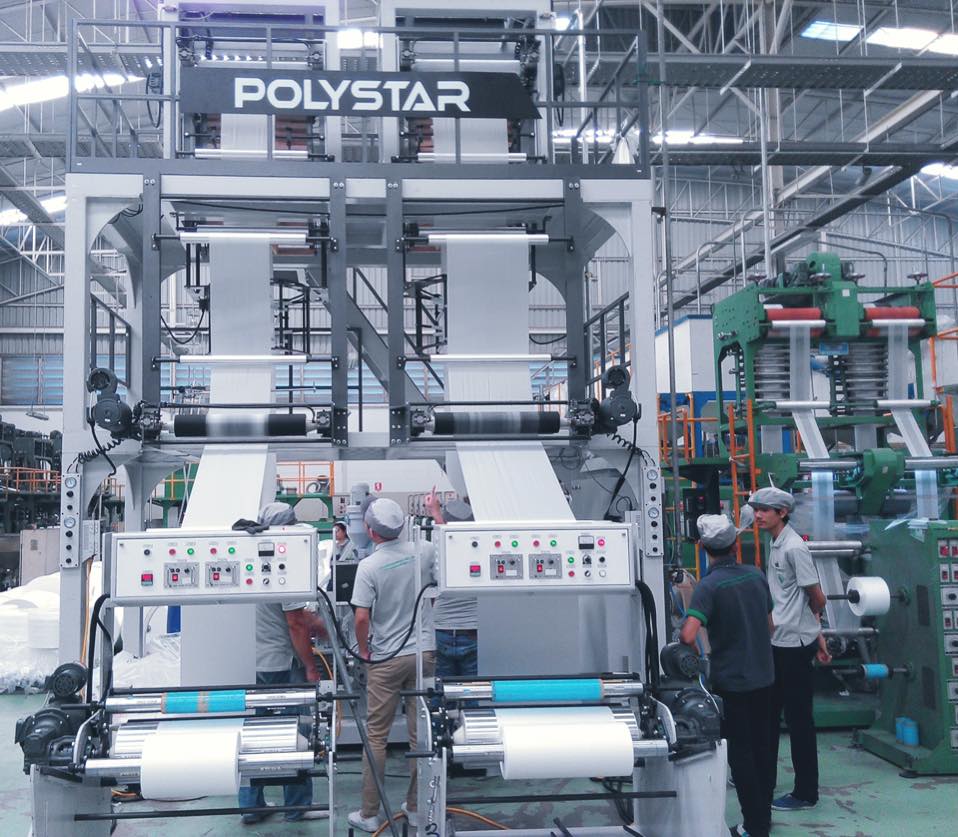

| T-shirt bag producer | HDPE film Producer |

Vietnam

The Vietnamese bag producer with monthly production of 1,500 tons doing 100% export to mainly European and Japanese markets.

HDPE thin T-shirt bags with virgin material for the Japanese market and LDPE thicker garbage bags (bag on rolls and draw tapes) with recycled material for the European markets can both be produced on the same DM55-750 machine.

The switch between producing HDPE/LDPE can be done simply by changing the die heads and air rings of the machines. Space saving, lower energy consumption, higher productivity are the reasons why the company continues to invest in POLYSTAR every year for both quality product and manufacturing efficiency. |

Indonesia

The ABA 3 layer blown film machine is mainly used for shopping, T-shirt and garbage bag production. The biggest advantage of the ABA is that a high percentage of calcium carbonate compound can be used in the middle (B) layer. Besides reducing a significant amount of virgin raw material used in the formula, another advantage of the ABA machine is that the 3-layer film that it produces is 30% stronger than the film produced by a monolayer extruder with the same thickness.

In some markets where shopping and T-shirt bag production has become extremely competitive, film producers are replacing their existing monolayer extruders with ABA 3 layer blown film machines to reduce production cost.

|

|

Recycling Industry |

|  |

| Thermoforming - PS, PP cups, trays producer | BOPP and laminated film producer |

Bolivia

Production waste from thermoformed PP trays, cups, spoons and PS utensils.

The largest plastic producer located in Bolivia with over 2,000 employees is currently recovering all of its industrial waste with two POLYSTAR recycling machine HNT-120V, processing in total of 1,000 kg/hour.

The recycling machine can flexibly handle both PP and PS thermoformed product, in addition to some of the PE and PP film waste. | Canada

BOPP and stretch film scraps and film on-roll can be turned into high quality pellets for reprocessing. POLYSTAR’s advanced cutter-compactor system can process material that is typically more difficult to recycle due to its special property, such as printed BOPP and stretch film that one normally faces problem with the traditional recycling systems. |

|

|

| POLYSTAR advantage |

| The design of the POLYSTAR pelletizing extruder is simple, and focused on the most important features for recyclers to have a stable operation in order to reduce down-time and lower production cost.

Easy operation

The emphasis on easy user-interface makes sure that the Initial training time and cost for (new) machine operators can be greatly reduced. The simplicity in design also makes it easy for the operators to perform maintenance on the machine.

Lower maintenance cost The cost of consumable parts is 2.5~3 times lower comparing to European machine suppliers of similar built quality.

Less waste generated – thanks to faster change between different types of materials. Professional recyclers often times have to change between different types of materials with different shapes and colors. POLYSTAR unique design has a much less change over time (up to 30~40%) during the “purging” process and therefore generate less production waste comparing to other recycling extruders. |