Material recycled in HDPE-plastic-bottles recycling granulator

| ||

| Granules | Hard plastic regrind | Fluff flakes |

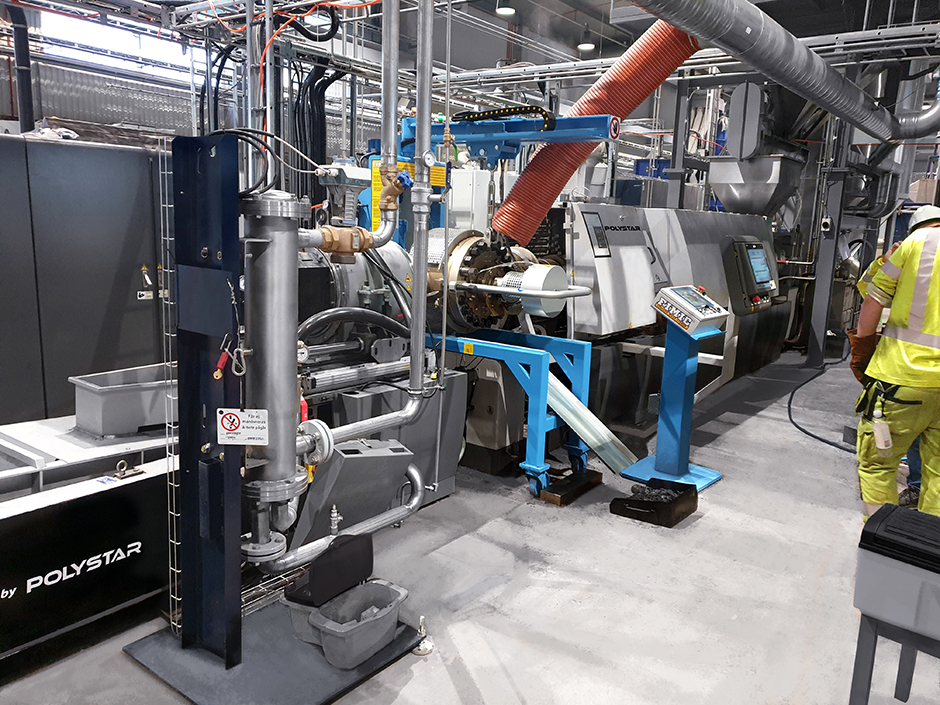

HDPE-plastic-bottles recycling granulator

| |

| HDPE-plastic-bottles recycling granulator is a universal recycling pelletizing machine suitable for pre-crushed, heavy rigid regrind scraps such as bottles, pipes, containers and lumps in the form of granules. Applicable materials are mainly HDPE, LDPE, PP, PA, PC, PU, PBU, ABS and others. |

| HDPE-plastic-bottles recycling granulator can also process light-weighted soft packaging material such as pre-crushed film flakes, PP raffia, PE/PP woven, PE foam and many others with the addition of a force feeder on the feeding hopper. |  |

| In the HDPE-plastic-bottles recycling granulator, material is fed into the hopper directly without the need for pre-heating before extrusion. When processing rigid regrind or compressed washed flakes (processed by a squeezer dryer), this system ensures a faster and easier machine starting and stopping process comparing to other systems. |

HDPE-plastic-bottles recycling granulator in customer's plant

| The Sweden reputed recycler, which is the professional recycler and collects plastics from waste electrical and electronic equipment (WEEE) and other products from the automotive sector such as bumpers, battery packs, engine piping, etc. These Post-Consumer waste are contained with iron particles, wood pieces and paper labels…etc. Thus, the turnkey solution from the material sorting, cleaning, drying and processing into the high end quality recycled pellets are the essential factors toward business success. Thanks to the simplest yet powerful design of POLYSTAR’s recycling machine, plus integrate with FIMIC’s advanced auto cleaning filtration system. It ensures the excellent filtration efficiency and continuously high output performance. |

| With POLYSTAR simplified and user-friendly structure design, the cooling temperature can be visible monitored and controlled via intelligent PLC control system, the average output of its Repro Direct 150 is reached up to 700~800 kg/hr for our business benefit constant contribution, impressively described by the factory director. As a professional recycler in the post consumer recycling industry, the excellent quality of the recycled pellets and high efficiency of machinery operation are the most important two indicators we pursue. Hence, we consider that the simplest yet powerful machine of POLYSTAR, and its high degree of fully automation control system can be met with our expectation, says by the customer. |

Why POLYSTAR HDPE-plastic-bottles recycling granulator

| High quality recycled pellets Up to 100% reusability back into your production line. Post-industrial waste generated from production of film, raffia and injection regrind can be recycled efficiently by HDPE-plastic-bottles recycling granulator and put right back into your production lines. Meaning less amount of new (raw) material needs to be used in your production. |

| Manufacturing with Precision CE certified HDPE-plastic-bottles recycling granulator with total quality control Adopts the latest design and manufacturing of screw and barrel to achieve maximum efficiency Strong research and design team |

| Service and Communication Overseas HDPE-plastic-bottles recycling granulator installation service and training are available |

Our Experience, Your Advantage

| |

HDPE-plastic-bottles recycling granulator

Are you from the EU regions?

Taiwantrade.com and iDealEZ.com uses analytical cookies and other tracking technologies to offer you the best possible user experience. By using our website, you acknowledge and agree to our cookie policy.

For more information on cookies or changing your cookies settings, read Taiwantrade & iDealEZ’s Privacy Policy.